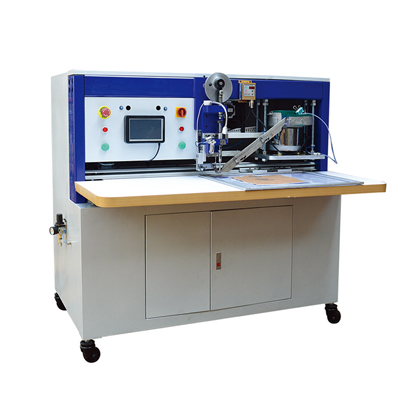

JYL-A6-4 Four Heads Industrial Automatic Computerized Rivets Nailing Fastening Bottom Attaching Machine for Shoes Bags Belts

Product description

JYL- A6 -4 four heads pattern studs attaching machine is suitable for take rivets/nails decoration on shoes ,bags ,belts ,jeans and suitcases,sofa furniture etc industry.

Product Specification

| Machine Type number | JYL-A6-4 |

| Applicable Industries: | Garment Shops, Machinery Repair Shops |

| Machinery Test Report: | Provided |

| Warranty of core components: | 1 Year |

| Core Components: | PLC |

| Place of Origin: | Guangdong, China |

| Brand Name: | JYL |

| Type: | Button attaching machine, Automatic |

| Voltage: | 220V |

| Dimension(L*W*H): | 1500*1400*1350MM |

| Weight: | 150kg |

| Certification: | CE |

| Warranty: | 1 Year |

| After-sales Service Provided: | Online support, Video technical support |

| Name: | Fast Speed |

| Product name: | Button attaching machine |

| Function: | Smooth |

| Suitable for: | Leather Prodution |

| Color: | White |

| MOTOR: | Servo Motor |

| Speed: | Auto |

| Control system: | Control System |

| Software: | AUTOCAD |

Product description

1. Stable performance,Precise positioning,High efficiency.

2. Suitable for 2-10mm diameter round four claw nails and square four claws nails in 4-10mm.

3. Four different rivets/nails can be attached in one time, to make diversified decoration on your products.

4. Best choice to save time and reduce labor cost during production.

5. The machine programming can be achieved by computer with a special software supplied along with the machine or by importing DXF. files created by other software.

6. Full automatically feeder, when the material thickness become thicker, it automatically turns to the pressure strength.

The Programmable Rivets Attaching Machine is widely used in industries that require precise, efficient, and repeatable riveting operations. Thanks to its programmable capabilities, this machine is suitable for:

Automotive Industry

Attaching metal brackets, interior components, seat structures, dashboard assemblies, etc.

Electronics Industry

Aerospace and Aviation

Appliance Manufacturing

Hardware and Metal Components

Furniture and Fixtures

Frequently Asked Questions (FAQ)

Q1: What is a Programmable Rivets Attaching Machine?

A: It is an automatic riveting system that uses a programmable control interface (usually PLC + touchscreen) to perform rivet inserting and fastening operations with high precision and repeatability.

Q2: What types of rivets can the machine handle?

A: The machine supports various types of rivets including solid, semi-tubular, blind, and custom rivets, depending on your configuration and application needs.

Q3: Can the machine be integrated into an automated production line?

A: Yes, it can be seamlessly integrated into automated or semi-automated production lines and can work with robotic arms, conveyors, and inspection systems.

Q4: Is it easy to change the rivet size or program settings?

A: Yes, the machine features a user-friendly HMI touchscreen that allows quick adjustment of rivet size, positioning, and pressure control via stored programs.

Q5: How is quality controlled during the riveting process?

A: The machine is equipped with servo control systems, force sensors, and optional vision inspection, ensuring every rivet is precisely placed and fastened.

Q6: What is the maintenance requirement?

A: Routine maintenance includes checking alignment, lubrication, sensor calibration, and software diagnostics. The machine is designed for easy upkeep and long service life.