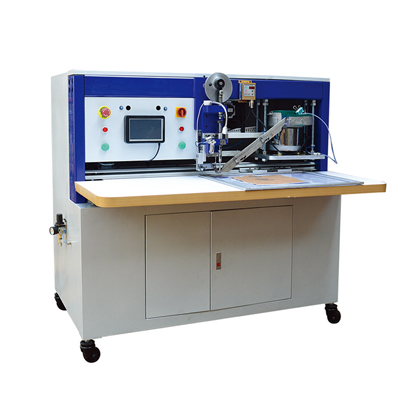

The JYL-A1 Auto Nailing Stud Attached Machine is a cutting-edge, energy-saving industrial solution designed for efficient and precise stud attachment. Ideal for applications in shoes, handbags, belts, and various leather goods, this computerized automatic stud nailing machine offers superior performance with minimal manual intervention.

Key Features and Functions

Versatile Nail Compatibility: Supports a wide range of nails including 210mm diameter round nails and square four-claw nails sized 410mm, accommodating diverse production needs.

Adjustable Settings: Allows users to easily control working speed, nailing force, and brightness to achieve optimal results based on material and stud type.

User-Friendly Operation: Safe and convenient to use, with simple adjustments to enhance efficiency and reduce operator fatigue.

Advanced Programming: Equipped with specialized software enabling programming via computer; supports importing DXF files from various CAD software, ensuring flexible and accurate design execution.

Automatic Feeding and Pressure Adjustment: Features a fully automatic nail feeder system and adaptive pressure control that adjusts automatically according to material thickness for consistent performance.

Stable and Precise: Delivers reliable operation with precise stud positioning and high-speed nailing, maximizing productivity and reducing material waste.

Applications

The JYL-A1 Stud Attached Machine is widely utilized in:

Footwear manufacturing – attaching decorative and functional studs on shoes

Leather goods – handbags, belts, and suitcases requiring durable stud attachment

Furniture upholstery – sofa and other furniture components needing stud embellishment or reinforcement

This automatic stud nailing machine is designed for industrial-scale production lines demanding high accuracy, speed, and repeatability. Its energy-saving design and computerized control ensure cost-effective operation, while the versatile nail compatibility and adaptive features make it suitable for a variety of materials and products.

What types and sizes of nails can the machine handle?

The machine supports round nails with diameters from 2mm to 10mm and square four-claw nails ranging from 4mm to 10mm.

How do I program the machine for different stud patterns?

You can program the machine using the supplied specialized software on your computer. It also supports importing DXF files created by other CAD software for precise pattern control.

Can the working speed and nailing force be adjusted?

Yes, the working speed, pressure strength, and brightness are all adjustable to fit different materials and stud types.

Is the machine easy to operate and safe?

Absolutely. The JYL-A1 is designed with user-friendly controls, safe operation features, and convenient adjustment options.

Does the machine automatically adjust to material thickness?

Yes, it features an automatic pressure adjustment that adapts to changes in material thickness to ensure consistent stud attachment quality.

What are the main application areas for this machine?

It is commonly used in manufacturing shoes, handbags, belts, suitcases, and furniture upholstery like sofas.

Does the machine require manual feeding of nails?

No, it includes a fully automatic nail feeding system for uninterrupted production.

What kind of maintenance is required?

Regular cleaning, lubrication of moving parts, and checking the feeder and programming system are recommended to maintain optimal performance.