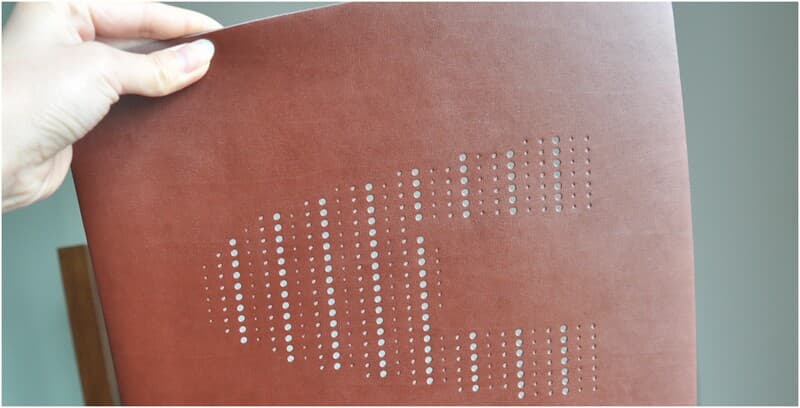

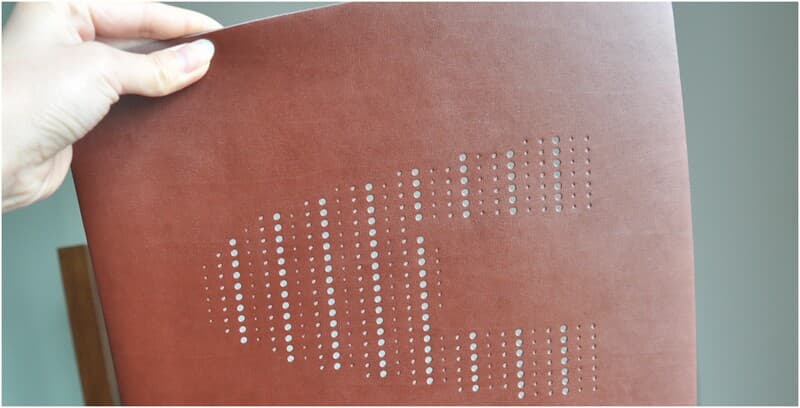

CNC leather punching machines are often referred to as handbag punching machine as well as leather punching machine upper and shoe vamping machines car seat punching machine and suitcase punching machines, etc. The machine is an integration between CNC and software technology. It has many advantages, including Speedy, high efficiency and no blackening, there is there is no smell, no burning. The automated punching machine could be utilized in the following industries Accessories for cars (breathable cushion) suitcases, bags, luggage and handbags, stationery leather shoes, breathable fabrics and advertising products, sofas and many other fields. It can be used with the following materials such as sheep and cattle leather, synthetic leather, EVA, PU PVC, plastics, diverse fabrics, paper curtains, leather accessories cars with leather seats mouse pads, and so on.

Product Description

The leather punching machine is electrical punching, which uses bent axle revolving to achieve loop movement, and punching the holes on leather, cloth, paper, foam, thin metal, PVC and other thin films.

Product Specification

| Item No. | JYL-A5-1 | JYL-A5-2 |

| Working Area | 600× 500mm | 600× 500mm |

| Speed | 420-1100PCS/min | 420-960PCS/min |

| Voltage | 110V-240V | 110V-240V |

| Pressure | 5-6KG/cm2 | 5-6KG/cm2 |

| Product size | 1800 ×1500× 1510mm | 2720 ×17100× 1500mm |

Main Features

speeds of leather punching machine is up to 420-1100 pcs /min.

Automatic punching machine made with JYL multi-axis CNC system, can installed 5 kinds of punch needles

Japan Fuji motor power

Large working area which is 600 * 500mm.

Can produce various patterns on the leather due to the adjustable angle of needles.

Can pouch complex patterns on the small area.

Lower noise, good quality of the hole, wouldn't burn compared to the laser-beam drilling machine

Easy to operate.

JYL-A5-2 Double head working stations , High efficiency. for mass production line.