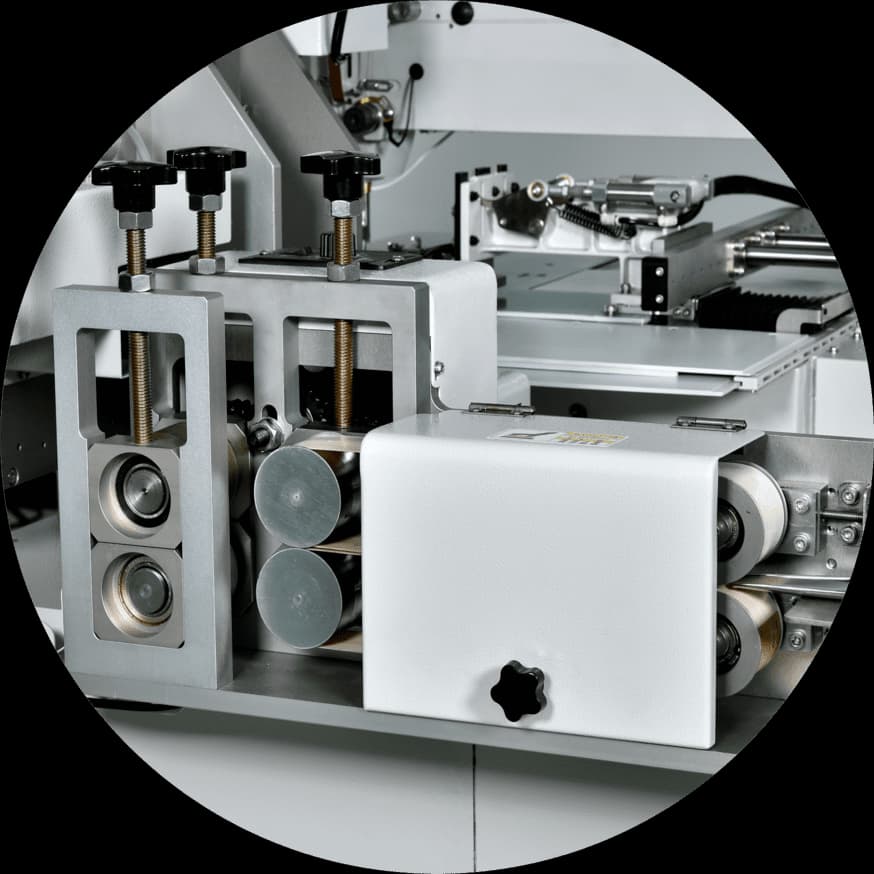

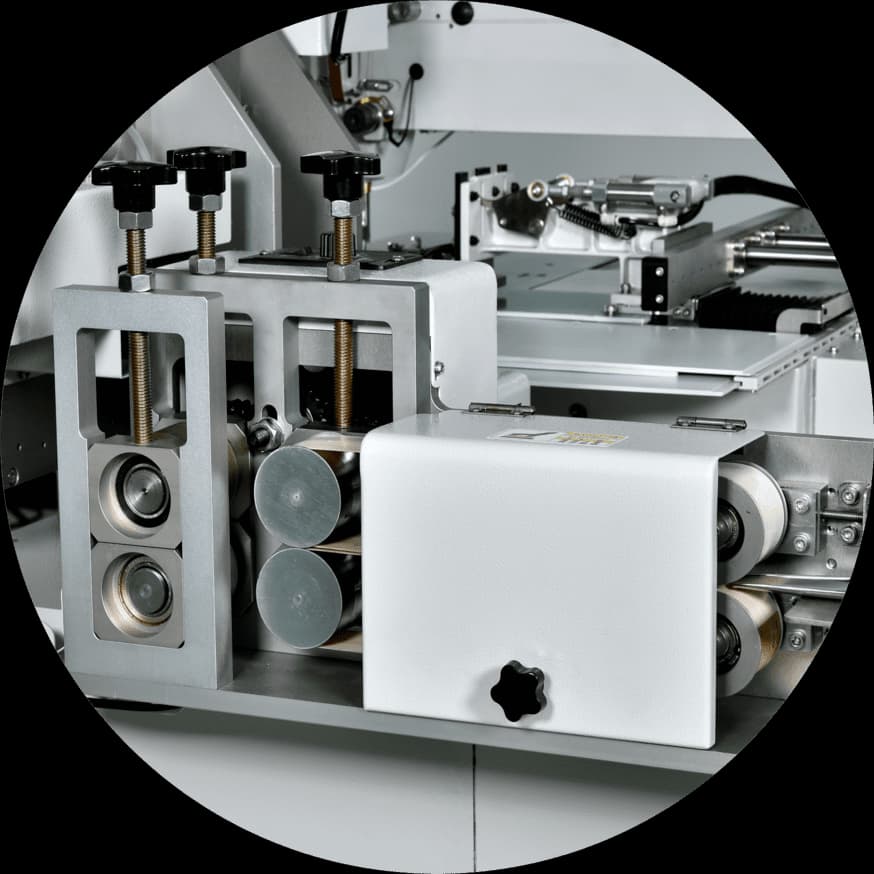

Fully Automatic Velcro & Webbing Sewing Machine

Product Description

This Computerized Velcro tape sewing machine is widely used for cap/ velcro webbing/ strap/ other similar products, like baseball cap adjusting strap, multicam name tape velcro, marine velcro tape, velcro mounting tape and etc.

Main Features

|  |  |  |

Winding threads in precise quantity by using electronic winding function. | Air pressure alarm (Alarm function activate when air pressure lower than 0.4 pa) | Automatic stripdrawing and ironing function | Warning alarmfunctions, machine canshutdown automatically when lack of bottom thread,thread breakage,needle breakage

|

Product Specification

| Machine No. | JYL-M3020G-MST |

| Working Area | L80-200mm W:160-220mm |

| Maximum Sewing Speed | 2800 RPM |

| Maximum No.of Stitehes | 20000stitches/pattern |

| Outer Pressure Foot | Penumatic |

| Medium Presser Height | 15mm |

| External Presser Foot Lifting | 30mm |

| Motor | 750W Direct-drive Servo Motor |

| Applicable Needle | DPxl7 |

| Air pressure | 05Mpa 1.8L/min |

| Stored programs | 1-999 patterns |

| Operation Type | 7.5″ Led Touch Panel |

| Supply voltage | 220V single phase |

| Size | 155x1220x1600mm |

| Weight | 380KG |

Key Features

Computerized control system supporting 1–999 programmable sewing patterns, with up to 20,000 stitches per design.

Electronic thread winding ensures the accurate preparation of thread quantity.

Smart alarm functions detect thread breakage, needle breakage, and air pressure drops below 0.4 Pa, and halt operations accordingly.

Fully automatic operation from strip drawing and ironing to cutting, folding, Velcro feeding, and sewing.

Adjustable settings for the length and width of both webbing and Velcro to accommodate various product specifications.

One operator can easily manage multiple machines due to the high level of automation.

7.5-inch LED touchscreen for intuitive operation and easy parameter adjustment.

Application Fields

This machine is suitable for a wide range of industries and products, including:

Apparel manufacturing: adjustable hat straps, Velcro name tags, children’s garments

Bags and accessories: backpacks, tactical pouches, belts

Marine equipment: Velcro closures for water-resistant gear

Sports and safety gear: protective clothing, reflective straps

Medical supplies: orthopedic straps, adjustable wraps

Advantages

Highly automated operation reduces manual labor

Consistent and accurate stitching results

Suitable for mass production

Simplifies complex sewing processes

Flexible settings to meet diverse production needs

For inquiries, sample requests, or customized solutions, please contact us directly.

FAQ

1. What materials can this machine handle?

This machine is designed to work with a wide range of materials, including Velcro (hook and loop tape), nylon webbing, polyester straps, and other similar synthetic or fabric tapes.

2. Can the machine be customized for different webbing sizes?

Yes, both the length and width of webbing and Velcro tape can be adjusted flexibly to suit your specific production requirements.

3. Is it easy to operate? Do operators need special training?

The machine features a 7.5-inch LED touchscreen interface that is intuitive and user-friendly. Most operators can quickly become proficient after a brief training session.

4. What kind of sewing patterns does the machine support?

The machine can store and execute up to 999 different sewing patterns, with each pattern allowing for a maximum of 20,000 stitches.

5. How does the machine ensure quality and reliability during production?

It includes multiple smart alarm functions that automatically stop the machine in case of thread breakage, needle breakage, or insufficient air pressure. This helps reduce waste and ensures consistent product quality.

6. How many machines can one operator manage?

Due to the high level of automation, one skilled operator can usually handle multiple machines at the same time, depending on the workflow setup.