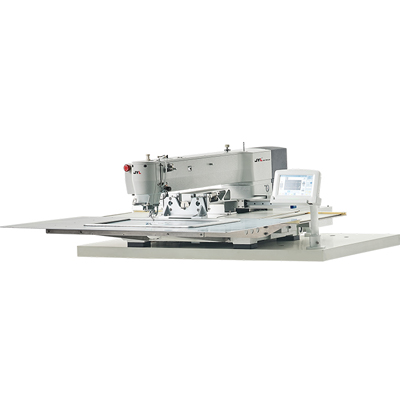

Electronic Industrial Bartack Sewing Machine for Shoes Lace Hole

The JYL Bartack line offers 28 stitch machines up to 42, to meet the demands of individuals. Another option is the electronical version of the Bartack stitching machine, which includes sewing patterns. Another type of machine is the Global Bartack 430D Series, which is for computer-controlled, electronic bar tacking and can sew up to 47 different patterns at one time. All these options are perfect for custom stitching and because of this possibility, there are tons of possibilities!

Product Application

This automatic programming industrial bartack machine is suitable for industrial sewing various surface fabric, like men's /women's/denim/ knitwear/underwear/bags/shoes.

Main Features

According to the sewing process requirements of hight quality sewing.

Low noise, low vibration and a rigid frame.

Widely used in clothing , handbags, shose and other sewing process.

Product Specification

| Item No. | JYL-B430D bar tacker sewing machine |

| Sewing Area | 40x30mm |

| Maximum Sewing Speed | 3200r.p.m |

| Sewing Trace | Single Needle Flat Seam |

| Stitches length | 0.1mm-12.7mm |

| Feeding | Intermittent feeding |

| Needle | DP*5 14# |

| Foot driving method | S-pulse motor drive |

| Pressing foot height | Standard 14mm,Maximum 17mm(when Reverse lifting needle) |

| Maximum Sewing Speed | 50000stitches/pattern |

| Standard pattern number | 100 patterns (Extended to store arbitrary graphics) |

| Thread Tension Device | Manual clamp /electromagnetic clamp |

| Hook | Semi-rotating standard hook or semi-rotating double hook |

| Motor | 600W minitype AC Servo motor (direct drive mode) |

| Rated power | 600W |

| Supply voltage | AC 220V±10% 50/60Hz |

| Application | Medium thickness material |

| Machine Size | 1200*670*1270MM |

| Weight | 95KG |

Applications

Sports Footwear

Provides reinforced stitching for high-stress areas, enhancing durability in sports shoes.

Leather Shoes

Ensures a professional finish and robust hold for premium leather footwear.

Casual Footwear

Adds strength and style to casual and everyday shoes.

Safety Boots

Delivers heavy-duty stitching to meet the rigorous demands of safety footwear.

Advantages

Consistency: Guarantees uniform stitching, reducing defects and enhancing product quality.

Cost-Effectiveness: Speeds up production while minimizing material wastage.

Customization: Adaptable settings for various shoe designs and styles.

Reliable Performance: Ensures high-quality stitching across all footwear types.

Ease of Use: Designed for both novice and experienced operators.

Support and Maintenance: Backed by excellent after-sales service and technical support.