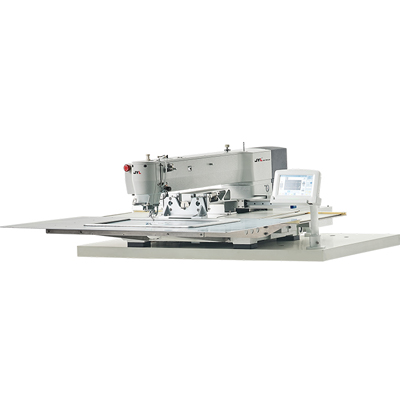

A CNC Stitching Machine is a computer-controlled sewing device used in various industries for precise and automated stitching. It offers accuracy, automation, and versatility, handling complex stitching patterns and enhancing productivity. Ideal for textiles, leather goods, and more, it reduces errors, allows customization, and integrates into production lines effectively.

High Precision:

Equipped with CNC technology, these machines can execute precise stitching patterns and dimensions, ensuring consistency and accuracy in production.

Versatile Applications:

CNC stitching machines are suitable for a wide range of materials, including fabrics, leather, synthetic materials, and more. They are ideal for various applications, such as garment manufacturing, automotive interiors, bags, and soft furnishings.

User-Friendly Interface:

Many CNC stitching machines come with intuitive software that allows operators to easily program stitching patterns and adjust settings. This user-friendly interface minimizes the learning curve and enhances productivity.

Automated Operation:

With automated functions such as threading, cutting, and positioning, CNC stitching machines significantly reduce manual labor and increase efficiency. This automation leads to faster production cycles and reduced operational costs.

Customizable Stitch Patterns:

Users can create and save custom stitch patterns, enabling the production of unique designs tailored to specific requirements. This flexibility is essential for businesses looking to differentiate their products.

Robust Build Quality:

Designed for industrial use, CNC stitching machines are built with durable materials to withstand heavy workloads and ensure longevity. Their robust construction minimizes downtime and maintenance needs.

Multi-Needle and Multi-Thread Capabilities:

Many models offer multi-needle and multi-thread options, allowing for complex stitching techniques and intricate designs, which are essential for high-end fashion and specialized products.

Integrated Safety Features:

Modern CNC stitching machines include safety mechanisms such as emergency stop buttons, automatic shutoff, and protective covers to ensure operator safety during operation.

Product Specification

| Item No, | JYL-B6040G |

| Sewing Area | 600x400mm |

| Maximum Sewing Speed | 2800r.p.m |

| Sewing Trace | Single Needle Flat Seam |

| Feeding | Intermittent feeding(Pulse motor drive) |

| Stitches length | 0.05mm-12.7mm |

| Maximum stitches | 20000stitches per pattern |

| Stored Stitches | Built-in memory can store 500000 stitches |

| Foot driving method | S-pulse motor drive |

| Pressing foot height | 25-30mm |

| Hight of big presser foot | Maximum 30mm |

| Air pressure | 0.5MPa 1.8L/mim |

| Supply voltage | AC 220V Single- pahse |

| Media | With sound alarm device |

| Intermittent pressure lift | 22 mm |

| Stored programs | 1-999patterns |

| Machine Size | 1660×1400×1310mm |

| Weight | 380KG |

CNC (Computer Numerical Control) sewing machines offer numerous advantages over traditional sewing methods. Here are some key benefits:

Precision and Consistency:

CNC sewing machines deliver high precision in stitching, ensuring uniformity across all products. This consistency is crucial for maintaining quality standards, particularly in mass production.

Increased Efficiency:

The automation of sewing processes significantly speeds up production times. CNC machines can operate continuously with minimal supervision, allowing for higher output compared to manual sewing.

Reduced Labor Costs:

With automated features, CNC sewing machines require fewer operators, leading to lower labor costs. This efficiency allows skilled workers to focus on more complex tasks rather than repetitive sewing.

Customizable Stitch Patterns:

Users can easily program and modify stitch patterns, enabling the creation of intricate designs tailored to specific customer needs. This flexibility enhances creativity in product development.

Versatility Across Materials:

CNC sewing machines can handle a variety of fabrics, including heavy materials like leather and upholstery, as well as lighter textiles. This versatility makes them suitable for multiple industries.

Lower Material Waste:

The precision of CNC machines helps reduce fabric waste during cutting and stitching, which can lead to cost savings and a more sustainable production process.

Advanced Features:

Many CNC sewing machines come equipped with advanced features like automatic thread trimming, tension control, and error detection, improving overall productivity and reducing downtime.

Safety Enhancements:

Modern CNC machines are designed with safety features such as emergency stop buttons and protective guards, ensuring a safer working environment for operators.

Simplified Training:

The user-friendly interfaces of CNC sewing machines facilitate quicker training for operators, allowing them to become proficient in a shorter time frame.

Integration with Design Software:

CNC sewing machines can be integrated with design software, allowing for seamless transitions from design to production. This integration enhances workflow and efficiency in the design process.

Sewing CNC Machine Maintenance

Proper maintenance of CNC sewing machines is vital for longevity and optimal performance. Key practices include regular cleaning, lubrication, and needle inspection, as well as checking thread quality and tension. Additionally, performing electrical and mechanical checks, keeping software updated, and calibrating the machine are essential. Training operators on maintenance procedures ensures issues are promptly recognized and addressed. Implementing these practices helps enhance the machine's efficiency and extends its lifespan.

Applications:

Apparel Manufacturing: Widely used in the clothing industry, especially for high-quality garments and custom-made clothing, offering precise decorative and functional stitching.

Footwear Production: Ideal for stitching shoe uppers and soles, especially on materials like leather and synthetic fabrics, ensuring both strength and aesthetics.

Automotive Interiors: Used in stitching car seats, headliners, and floor mats, providing high-quality stitching results that guarantee durability and appearance.

Leather Goods: Extensively used in the production of leather products like handbags, wallets, shoes, etc., providing fine stitching and decorative finishing.

FAQ

What is a CNC stitching machine?

A CNC stitching machine is an advanced sewing machine that uses computer numerical control technology to automate stitching processes, ensuring precision and consistency in production.

What are the key features of CNC stitching machines?

Key features include high precision stitching, automated operation, customizable stitch patterns, versatility with various materials, and user-friendly interfaces.

What industries commonly use CNC stitching machines?

Industries such as textiles, automotive, leather goods, upholstery, and garment manufacturing frequently utilize CNC stitching machines for their efficiency and precision.

How does CNC technology enhance stitching accuracy?

CNC technology allows for precise programming of stitch patterns and dimensions, resulting in consistent quality and reduced errors compared to manual sewing methods.

What maintenance is required for a CNC stitching machine?

Regular maintenance includes cleaning, lubrication, needle inspection, thread tension adjustment, and mechanical checks to ensure optimal performance and longevity.

Can CNC stitching machines handle multiple fabric types?

Yes, CNC stitching machines are designed to work with a wide range of fabrics, including heavy materials like leather and upholstery, as well as lighter textiles.

What are the benefits of using CNC stitching machines over traditional sewing machines?

Benefits include increased efficiency, reduced labor costs, customizable stitch options, lower material waste, and improved overall quality of finished products.

How do operators program CNC stitching machines?

Operators can program the machines using intuitive software that allows them to create and save stitch patterns, adjust settings, and manage production runs.

What safety features are commonly found in CNC stitching machines?

Common safety features include emergency stop buttons, protective covers, and automatic shutoff mechanisms to ensure operator safety during operation.