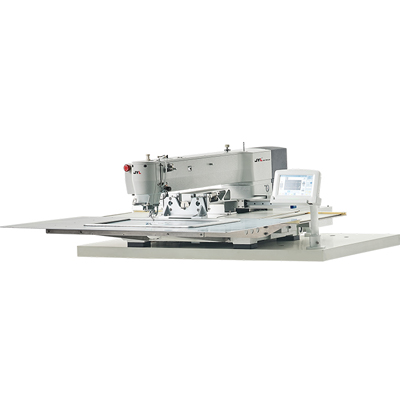

Product Description

The computerized pattern sewing machine is a high-precision, high-efficiency automated sewing device widely used in the apparel, home textile, footwear, and other industries for pattern stitching. The machine is controlled by a computer program, enabling it to execute complex pattern designs accurately, replacing traditional manual sewing methods and enhancing both production efficiency and stitching quality. With its high automation, ease of operation, and reliable performance, it has become an essential tool in modern manufacturing processes.

Product Specification

| Item No. | JYL-B1510G-P |

| Sewing Area | 150x100mm |

| Maximum Sewing Speed | 2800r.p.m |

| Sewing Trace | Single Needle Flat Seam |

| Feeding | Intermittent feeding(Pulse motor drive) |

| Stitches length | 0.05mm-12.7mm |

| Maximum stitches | 20000stitches per pattern |

| Stored Stitches | Built-in memory can store 500000 stitches |

| Foot driving method | S-pulse motor drive |

| Pressing foot height | 25-30mm |

| Air pressure | 0.5MPa 1.8L/min |

| Supply voltage | AC 220V Single- pahse |

| Hight of big presser foot | Maximum 30mm |

| Media | With sound alarm device |

| Intermittent pressure lift | 22mm |

| Stored programs | 1-999patterns |

| Machine Size | 1200×800×1400MM |

| Weight | 150KG |

Key Features

1.Precision Control System

Equipped with an advanced computer control system, this machine ensures high-precision pattern stitching, ensuring each stitch meets design specifications.

2.Supports Various Pattern Designs

Patterns can be uploaded through USB or network interfaces, supporting various file formats such as DST, EXP, JEF, etc. Users can also create custom designs based on their needs.

3.High-Speed Stitching

Driven by a high-speed motor, the machine can stitch up to 5000 stitches per minute, significantly increasing production efficiency and reducing cycle times.

4.Automatic Thread Cutting Function

The machine includes an automatic thread-cutting system that trims the thread at the end of each stitching cycle, minimizing manual intervention and boosting productivity.

5.Touchscreen Interface

The machine features a large touchscreen interface, allowing users to easily adjust parameters such as speed, pattern size, stitch length, and more. The interface is user-friendly and intuitive.

6.Stable and Low Noise Operation

With high-quality precision components and unique shock-absorbing design, the machine operates smoothly with minimal noise, extending its service life and improving the working environment.

7.Smart Error Detection and Alerts

The machine is equipped with a smart diagnostic system that monitors its operational status in real-time. In case of malfunction, the system alerts the user and provides troubleshooting guidance to quickly resume production.

8.Versatility

This machine is not only ideal for stitching various patterns but also for embroidering text, logos, icons, and other special designs, making it highly versatile in different industries.

Applications

1.Apparel Manufacturing

The machine can quickly and accurately stitch various patterns, such as embroidery, logos, and designs, making it ideal for clothing, hats, and shoes production.

2.Home Textiles

It is perfect for decorative stitching on bed linens, curtains, sofa covers, and other home textile products, adding aesthetic value and enhancing the final product.

3.Advertising Industry

The machine can stitch logos, advertisements, and slogans onto various fabrics, helping to enhance brand visibility and marketing effectiveness.

4.Custom Clothing

It supports customized stitching, making it an excellent solution for personalized clothing production, including complex design patterns.

Advantages and Conclusion

1.Efficient and Energy-Saving

Compared to traditional sewing machines, it saves labor, increases production capacity, and lowers costs.

2.Smart and User-Friendly Operation

The advanced computer system simplifies operation, reducing the skill level required and making the machine easier to use for operators.

3.Flexible Design Support

The machine supports various pattern designs and formats, meeting the diverse needs of customers.

4.Wide Fabric Compatibility

It can handle a wide range of fabrics, making it adaptable to various market demands.

FAQ

What types of patterns can be stitched with a computerized pattern sewing machine?

A computerized pattern sewing machine can stitch a wide variety of patterns, including embroidery designs, logos, text, icons, and intricate decorative stitches. It supports file formats such as DST, EXP, JEF, PES, and more, allowing users to upload custom designs.

How do I upload a pattern design to the sewing machine?

Pattern designs can be uploaded to the machine via a USB drive, network connection, or direct upload through compatible software. Once uploaded, the machine's control panel allows you to select and customize the pattern as needed.

What is the maximum stitching speed of a computerized pattern sewing machine?

The maximum stitching speed of most computerized pattern sewing machines is around 5000 stitches per minute, which significantly increases productivity compared to traditional manual stitching methods.

Can the machine handle different fabric types?

Yes, the machine is highly versatile and can stitch on a variety of fabrics, including cotton, wool, silk, leather, and synthetic materials. This makes it suitable for applications across multiple industries, including apparel, home textiles, and advertising.

How does the automatic thread cutting function work?

The automatic thread cutting function trims the thread at the end of each stitching cycle. It eliminates the need for manual thread trimming, saving time and ensuring a cleaner finish on the stitched product.