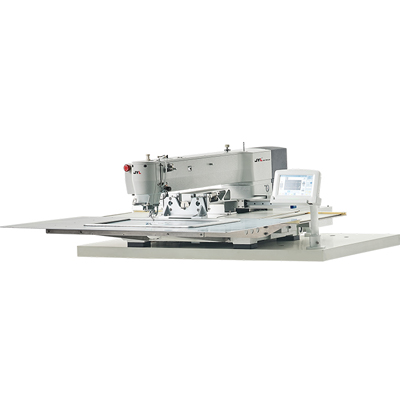

JYL sewing automation boasts an inventory of one the most extensive as well as competitive prices on computer-controlled machines that can be programmed. If you're seeking to automate your sewing machine and cut down on the cost of labor, we can help. Our experienced advisors are available to guide you through the procedure. This automatic computerized industrial sewing machines is suitable for stitching various surface fabric, like men's /women's/denim/ knitwear/underwear/bags/shoes.

Main Features

Suitable for applications such as men's /women's/denim/ knitwer/underwear/bags/shoes.

Strong data compatiblity can greatly reduce the duplication of patterns input.

The invention is provided with a quick clamp device.

Product Specification

| Item No. | JYL-B4530G |

| Sewing Area | 450x300mm |

| Maximum Sewing Speed | 2800r.p.m |

| Sewing Trace | Single Needle Flat Seam |

| Feeding | Intermittent feeding(Pulse motor drive) |

| Stitches length | 0.05mm-12.7mm |

| Maximum stitches | 20000stitches per pattern |

| Stored Stitches | Built-in memory can store 500000 stitches |

| Foot driving method | S-pulse motor drive |

| Pressing foot height | 25-30mm |

| Hight of big presser foot | Maximum 30mm |

| Air pressure | 0.5MPa 1.8L/mim |

| Supply voltage | AC 220V Single- pahse |

| Media | With sound alarm device |

| Intermittent pressure lift | 22 mm |

| Stored programs | 1-999patterns |

| Machine Size | 1450×1200×1260mm |

| Weight | 285KG |

Key Features

Digital Control Panel: Most programmable sewing machines are equipped with an intuitive digital control panel that allows users to select patterns, adjust settings, and monitor progress with ease. The clear LCD screens display detailed information, including stitch selection and length, ensuring precision in every project.

Built-in Stitch Patterns: These machines come with a variety of built-in stitch patterns, from basic straight and zigzag stitches to more complex decorative and embroidery stitches. Users can easily choose and customize stitches to suit their sewing needs.

Memory Function: Programmable sewing machines have memory functions that allow users to save custom stitch patterns and sequences. This feature is particularly useful for creating repetitive designs, making it easier to replicate patterns across multiple projects.

Automatic Needle Threading: Many models include an automatic needle threading system, which simplifies the process of preparing the machine for sewing. This feature saves time and reduces frustration, allowing users to focus on their creativity.

Adjustable Speed Control: Programmable sewing machines often feature adjustable speed settings, enabling users to sew at their preferred pace. This flexibility is particularly beneficial for intricate tasks that require more control and precision.

USB Connectivity: Some advanced models offer USB connectivity, allowing users to transfer designs and patterns directly from a computer to the sewing machine. This feature expands creative possibilities and enables access to a wide range of online resources.

Versatile Presser Feet: Programmable sewing machines come with various presser feet designed for specific sewing techniques, such as quilting, embroidery, and buttonholes. These interchangeable feet enhance the machine’s versatility, accommodating different fabric types and project requirements.

Sewing Assistant Functions: Many programmable sewing machines include built-in sewing assistants that provide guidance on techniques, stitch selection, and troubleshooting. This feature is especially helpful for beginners and those looking to expand their sewing skills.

LED Lighting: Good visibility is essential for sewing projects, and most programmable machines are equipped with LED lighting that illuminates the workspace. This feature helps users see their work clearly, reducing eye strain during long sewing sessions.

Durability and Build Quality: Programmable sewing machines are typically built with high-quality materials to ensure durability and longevity. A sturdy construction enhances the machine’s performance, making it capable of handling various sewing tasks.

Applications

Programmable sewing machines are suitable for a wide range of applications, including:

Fashion Design: Ideal for creating custom garments, alterations, and intricate designs in the fashion industry.

Quilting: Equipped with specialized features for quilting, these machines allow for precision stitching and beautiful patterns.

Home Decor: Perfect for crafting curtains, cushions, and other home furnishings with personalized designs.

Embroidery: Many programmable sewing machines support embroidery functions, enabling users to add decorative elements to their projects.

Craft Projects: Suitable for hobbyists, these machines facilitate various craft projects, from bags to stuffed toys.

Shoe Tongue Loop Sewing Machine:

A shoe tongue loop sewing machine is specially designed for attaching loops onto the tongues of shoes. It ensures precise and secure stitching of loops, contributing to the overall durability and aesthetics of the footwear. This machine streamlines the manufacturing process, improving efficiency and maintaining consistent quality in shoe production.

Double Needle Pattern Sewing Machine:

A double needle pattern sewing machine is a versatile tool used in sewing to create parallel rows of stitches with two needles simultaneously. It's ideal for decorative stitching, hems, and topstitching, offering enhanced durability and aesthetics. This machine is commonly used in garments, bags, and upholstery to achieve professional and intricate designs efficiently. It saves time by stitching two lines at once, adding a polished and symmetrical finish to a wide range of sewing projects.

Rotary Head Herringbone Sewing Machine:

A rotary head herringbone sewing machine is a specialized device used for creating herringbone patterns on various fabrics. It features a rotary sewing head that moves in a zigzag motion, producing the distinctive herringbone design. This machine is commonly employed in textile industries for manufacturing garments, home textiles, and decorative fabrics. Its unique sewing technique adds a stylish and textured look to fabrics, making it a valuable tool for enhancing visual appeal and creativity in sewing projects. The rotary head design ensures precision and efficiency in producing intricate herringbone patterns.

Cyclic Displacement Pattern Sewing Machine:

A cyclic displacement pattern sewing machine is an innovative device used to create intricate and repetitive displacement patterns on fabrics. This machine utilizes programmed cyclic movements to precisely displace the fabric while stitching, resulting in unique and eye-catching designs. It's often employed in textile and fashion industries to add dynamic textures and visual interest to clothing, accessories, and home decor items. The cyclic displacement technique allows for automated creation of complex patterns, saving time and ensuring consistency. This advanced sewing machine opens up new possibilities for artistic expression and customization in sewing projects, making it a valuable tool for creative designers and manufacturers.

Cylinder Jeans Sewing Machine:

A cylinder jeans sewing machine is a specialized tool designed for sewing curved or cylindrical sections of jeans, such as the legs and waistbands. Its cylindrical arm allows for easy manipulation of denim fabric, ensuring smooth and even stitching around curved areas. This machine is crucial for producing well-fitting jeans with professional-quality seams and details. It's commonly used in denim manufacturing and alterations, providing precise stitching and efficient production of jeans. The cylinder design accommodates the unique shape of jeans, making it an essential tool for achieving durability and comfort in denim apparel.

Shoes Bartack Sewing Machine:

A shoes bartack sewing machine is a specialized device used in footwear production to create strong and reinforced bartack stitches. Bartacks are dense and tightly spaced stitches that reinforce stress points on shoes, enhancing their durability. This machine is equipped with various stitching patterns and adjustable settings, allowing for precise customization based on the shoe design. It plays a crucial role in ensuring the longevity and quality of shoes by reinforcing areas like eyelets, loops, and seams. The shoes bartack sewing machine is a valuable tool in the footwear industry, contributing to the production of long-lasting and reliable shoes that can withstand daily wear and tear.