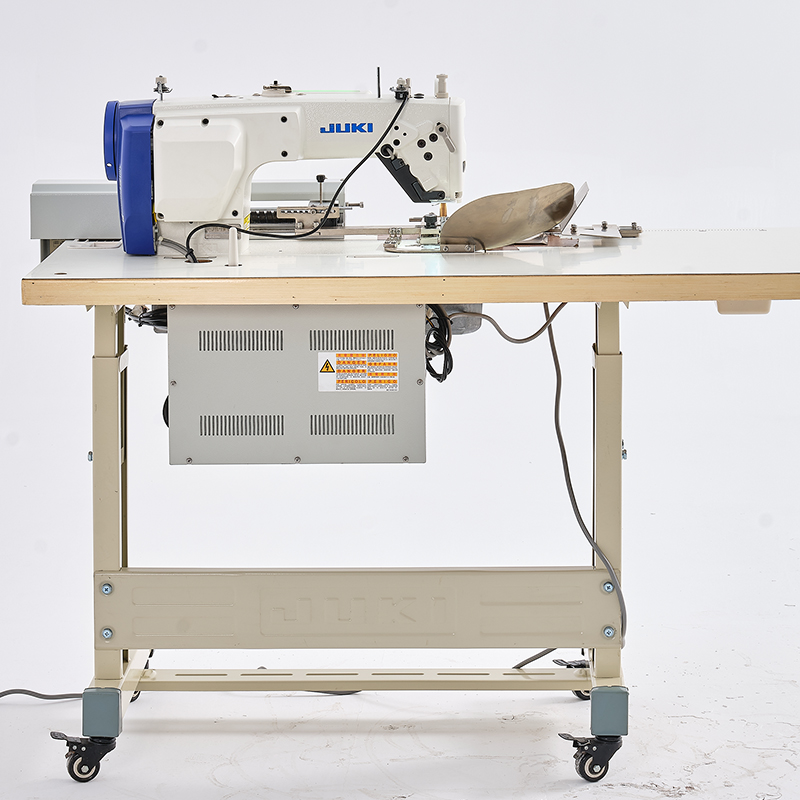

The Stitch Hat Machine, also known as the Fisherman Hat Sewing Machine, is a versatile and efficient tool designed specifically for crafting stylish and high-quality hats. With its specialized features and capabilities, the Stitch Hat Machine simplifies the hat-making process, allowing users to create professional-grade fisherman hats effortlessly. From stitching the brim to sewing the crown, this machine provides precise and consistent results, ensuring that each hat is beautifully crafted with attention to detail.

Advantages of Stitch Hat Machine:

1. High-quality stitching: The Stitch Hat Machine is designed to deliver consistent and high-quality stitching, resulting in durable and well-crafted hats.

1. High-quality stitching: The Stitch Hat Machine is designed to deliver consistent and high-quality stitching, resulting in durable and well-crafted hats.

2. User-friendly: The Stitch Hat Machine is user-friendly, making it accessible for both beginners and experienced sewers to create professional-grade hats.

3. Adjustable settings: The Cap Stitching Machine allows for adjustable settings, such as stitch length and speed, providing customization options for different hat designs.

4. Durability: Built with durable materials and components, the Stitching Hat Machine is designed to withstand long hours of continuous use.

5. Speed: The Stitch Hat Machine's efficient stitching speed enables users to complete hat production in a shorter amount of time.

6. Cost-effective: Investing in a Stitch Hat Machine eliminates the need for outsourcing hat production, resulting in long-term cost savings.

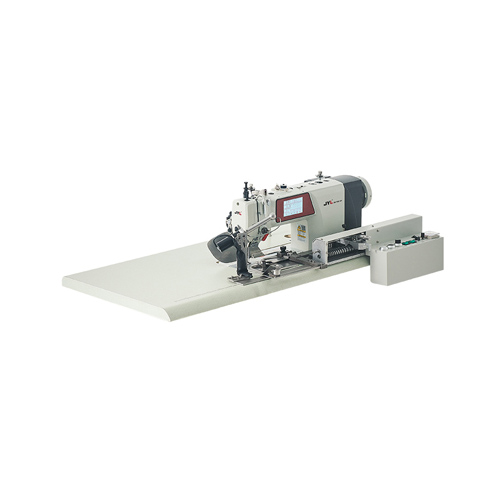

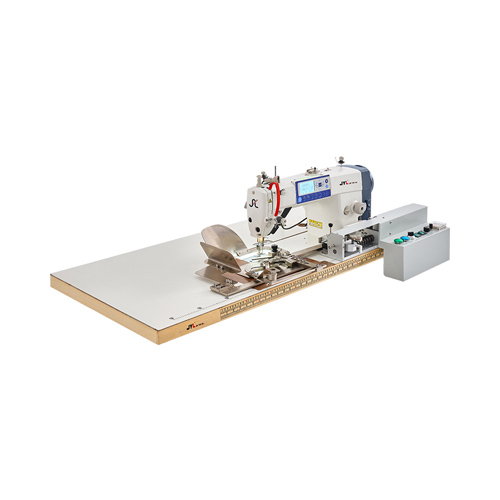

| Product Parameters |

Model No. | JYL-PM-01D / JYL-PM-01P |

Presser Foot Mode | Electronic/Mechanical |

Sewing Speed | 3000 rpm |

Maximum Stitches | 20000 stitches/pattern |

Stored Programs | 1-999 patterns |

Machine Size | 1200*540*730mm |

Applicable Needle | DP*17 |

Supply Voltage | AC 220V single phase |

Weight | 75KG |

Motor | 750W Direct Drive Servo Motor |

Working range | maximum radius R135 |

Cleaning the Stitch Hat Machine is essential to maintain its optimal performance and longevity. Here are some steps to clean the machine:

1. Power off and unplug: Before cleaning, ensure the Sewing Machine for Hat Making is powered off and unplugged to avoid any accidents.

2. Brush away dust and debris: Use a soft-bristle brush or a lint-free cloth to gently brush away any visible dust or debris from the machine's surface, including the needle area, bobbin case, and feed dogs.

3. Remove excess thread and lint: Carefully remove any excess threads or lint that may have accumulated in the stitch plate, bobbin area, and around the feed dogs. Use a small brush or a pair of tweezers to do this.

3. Remove excess thread and lint: Carefully remove any excess threads or lint that may have accumulated in the stitch plate, bobbin area, and around the feed dogs. Use a small brush or a pair of tweezers to do this.

4. Clean the bobbin case: Remove the bobbin case and clean it using a cloth dampened with a mild cleaning solution or warm soapy water. Dry it thoroughly before reinserting.

5. Lubricate moving parts: Apply a small amount of sewing machine oil to the designated lubrication points according to the manufacturer's instructions. This helps ensure smooth operation of moving parts.

6. Wipe down the machine: Use a gentle cleaning solution and a clean cloth to wipe down the external parts of the machine, including the body, controls, and motor area. Avoid using harsh chemicals or abrasive cleaners.

7. Check the needle and replace if necessary: Inspect the needle for any signs of wear or damage. Replace with a new needle if needed, following the machine's manual for proper needle selection.

8. Reassemble and test: Once the cleaning is complete, reassemble any removed parts and ensure they are securely in place. Perform a test run to ensure the machine is functioning properly before using it for hat making.

Regular cleaning and maintenance of the Stitch Hat Machine will prolong its lifespan and ensure optimal performance for all your hat-making projects.

FAQ

1. What types of hats can the Stitch Hat Machine make?

1. What types of hats can the Stitch Hat Machine make?

The Stitch Hat Machine can create a wide variety of hats, including Fisherman Hat, fedoras, sun hats, baseball caps, beanies, fascinators, and more.

2. Can the Stitch Hat Machine handle different fabrics?

Yes, the Stitch Hat Machine can work with various materials such as fabric, leather, straw, and felt, offering versatility in hat-making options.

3. Can the Stitch Hat Machine embroider hats?

Yes, the Stitch Hat Machine often has embroidery capabilities, allowing for decorative stitching and customization on hats.

4. Are accessories included with the Stitch Hat Machine?

The accessories included with the Stitch Hat Machine may vary depending on the model, but commonly include different presser feet, bobbins, and needles.

5. Is the Stitch Hat Machine noisy?

The noise level of the Stitch Hat Machine can vary depending on the model and speed, but modern machines are designed to operate quietly.

6. Does the Stitch Hat Machine require maintenance?

Like any other machine, the Stitch Hat Machine requires regular cleaning, lubrication, and needle replacement to ensure optimal performance.

Maintenance of Stitch Hat Machine

Proper maintenance of the Stitch Hat Machine is crucial to ensure its longevity and optimal performance. This includes regular cleaning to remove dust and debris, lubricating moving parts as recommended by the manufacturer, replacing needles when necessary, and following any specific maintenance instructions provided in the machine's manual. Additionally, it is important to handle the machine with care, avoiding excessive force or rough handling. By implementing these maintenance practices, you can keep your Stitch Hat Machine in excellent working condition for years to come.

1. High-quality stitching: The Stitch Hat Machine is designed to deliver consistent and high-quality stitching, resulting in durable and well-crafted hats.

1. High-quality stitching: The Stitch Hat Machine is designed to deliver consistent and high-quality stitching, resulting in durable and well-crafted hats.

3. Remove excess thread and lint: Carefully remove any excess threads or lint that may have accumulated in the stitch plate, bobbin area, and around the feed dogs. Use a small brush or a pair of tweezers to do this.

3. Remove excess thread and lint: Carefully remove any excess threads or lint that may have accumulated in the stitch plate, bobbin area, and around the feed dogs. Use a small brush or a pair of tweezers to do this.

1. What types of hats can the Stitch Hat Machine make?

1. What types of hats can the Stitch Hat Machine make?