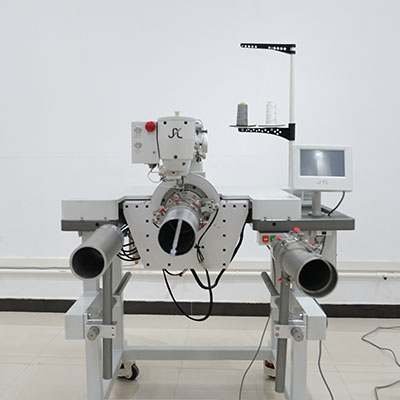

The Computerized Jeans Sewing Machine is a versatile and easy-to-use machine that is perfect for stitching denim and other thick fabrics. With its lengthened round bed design, the machine can easily sew slim type jeans with ease. Additionally, the new design trimming system ensures that thread ends are always kept short, while the easy quick clamp keeps the jeans in place during sewing. The large working area of 250mmx350mm provides plenty of space for pattern designs, and the 7.5 inch LCD operation panel makes it easy to navigate the machine's various functions. Finally, the automatic stop device of breakage thread protection and thread counting information display make it easy to keep track of your sewing progress and ensure that your stitches are always precise. This Cylinder Jeans Pattern Sewing Machine is widely used for Hat,Shoe uppers,heelpieces,and curve shape stitching.

Product Application:

Item No.

| JYL-G9220 |

| Sewing area | 250*200mm |

| Max sewing speed | 2300r.p.m |

| Stitch | 0.05-20.0mm |

| Max amounts of stitches | 20000 |

| Data storage | USB memory |

| Machine Size | 1480×1010×1150mm |

| Weight | 280KG |

| Motor | 750W direct-drive servo motor |

| Applicable needle | DP*17 |

Product Features

1. Cylinder Sewing Design

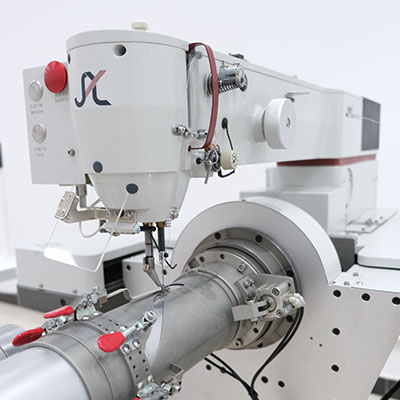

Cylinder Jeans Sewing Machine adopts 92mm diameter cylinder design, which is suitable for precise sewing of curved parts such as jeans leg, shoes upper, cap, etc. It avoids deformation of fabric and ensures even and smooth stitching.

2. Strong power, easy to penetrate heavy fabrics

High-torque direct-drive servo motor (750W) supports high-intensity sewing, easily penetrating through multiple layers of heavy denim, leather, canvas and so on.

High-pressure presser foot system for multi-layer sewing, ensure the fabric is stable and not shifting.

Adjustable presser foot height, adjusted for different thickness of fabrics to meet multiple production needs.

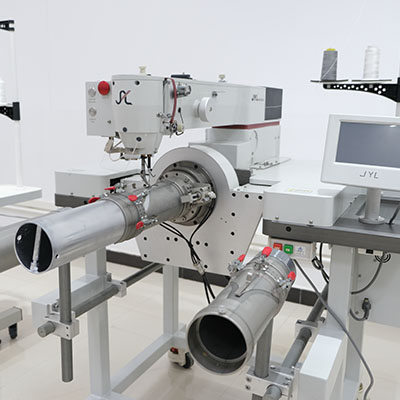

3. Intelligent operating system to improve production efficiency

7.5-inch LCD touch operation panel (supports Chinese and English interfaces, customizable in other languages), simplifies the operation process and makes sewing more accurate and faster.

Data storage and USB transfer, support pattern sewing mode, can store up to 20,000 stitches, easy to recall and reuse.

Automatic thread trimming system, new thread trimming device can shorten the thread, reduce manual trimming and improve work efficiency.

Thread breakage detection and counting function, real-time monitoring of the sewing status, to prevent thread breakage affecting the production schedule. 4.

4. High-speed sewing, precise stitching

Maximum sewing speed is up to 2300r.p.m, suitable for mass production.

Adjustable stitch length 0.05-20.0mm, supports detailed sewing and reinforced stitches.

Intelligent stitch control ensures even stitch length and avoids skipped stitches and thread breakage problems.

5. Highly flexible and suitable for a variety of application scenarios

Hat, shoe upper and heel sewing: suitable for shoe and hat industry, providing delicate curve sewing effect.

Leather products sewing: suitable for leather bags, belts, sofa leather and other high-end leather goods processing.

Jeans, work pants sewing: suitable for jeans, work pants, jackets and other heavy apparel sewing with precision.

Product Application Industries

Apparel manufacturing: specially built for denim apparel (such as jeans, jackets), supporting mass production.

Shoe processing: widely used in vamp, heel, insole sewing, improve the quality of shoe processing.

Hat sewing: suitable for precise curved surface sewing of all kinds of baseball caps, cowboy hats, work caps.

Leather products: Suitable for high-end leather processing of bags, belts, wallets, leather accessories, etc.

Automobile interior: can be used for automobile seat, steering wheel cover, leather door decoration sewing.

Why choose our Cylinder Jeans Sewing Machine?

High precision intelligent sewing: computerized control system ensures the accuracy of each stitch and reduces human error.

High Productivity: Automatic thread cutting, intelligent stitch control, quick clamping, significantly increase productivity.

High Stability: Imported core components are used to ensure the equipment is stable and durable, reducing the failure rate.

Professional technical support: Provide equipment training and maintenance services to protect customers' long-term efficient use.

Multi-industry application: applicable to denim apparel, footwear, leather goods, hats, car interiors and other industries.