Crafted for high-precision and high-efficiency sewing on curved surfaces, the Double Station Caps Visor Sewing Machine is the ideal solution for modern cap and footwear production. Originally developed for sewing on bags, hats, and shoe uppers, this machine is now widely applied in the mass production of cap visors, thanks to its advanced features and reliable performance.

| Machine No. | JYL-M3020G-SW |

| Working Area | 300 mm X 200 mm |

| Maximum Sewing Speed | 2800r.p. m |

| Maximum No.of Stitches | 30000stitches /pattern |

| Pressing foot height | 25-30 mm |

| Power | 3500W |

| Air pressure | 0.6Mpa 1.8L/min |

| Stored programs | 1-999 patterns |

| Operation Type | 7.5’ Lcd Touch Panel |

| Supply voltage | Ac 220v single phase |

| Size | 1800*1240*1400 mm |

| Net Weight | 400KG

|

Product Features & Benefits

Dual Station Design

Enables continuous and alternating production, improving operational efficiency for medium to large-scale manufacturers.

Precision Curved Surface Stitching

Specialized for sewing cap visors and shoe uppers with seamless accuracy on curved forms.

Automatic Monitoring System

Includes broken thread/needle detection, bottom thread monitoring, and auto-shutdown for safety and productivity.

Cooling-Enhanced Needle Operation

Reduces thread breakage and needle wear through an integrated needle cooling mechanism.

Electronic Thread Winding

Ensures precise thread quantity, reducing waste and enhancing stitch consistency.

Air Pressure Alert System

Automatically issues a warning and halts operations if air pressure drops below 0.4Mpa.

Second Wire Clamping System

Improves thread tension control and reduces skip stitching.

Perfect for Industrial Use

This machine is a trusted choice for:

Hat manufacturers producing customized visors

Footwear factories sewing upper decorations

OEM/ODM suppliers needing programmable sewing solutions

Textile product manufacturers requiring dual-station automation

Key Applications

Sewing Curved & Flat Hat Visors

Baseball caps, snapbacks, trucker hats

Shoe uppers and upper decorations

Bags and structured textile components

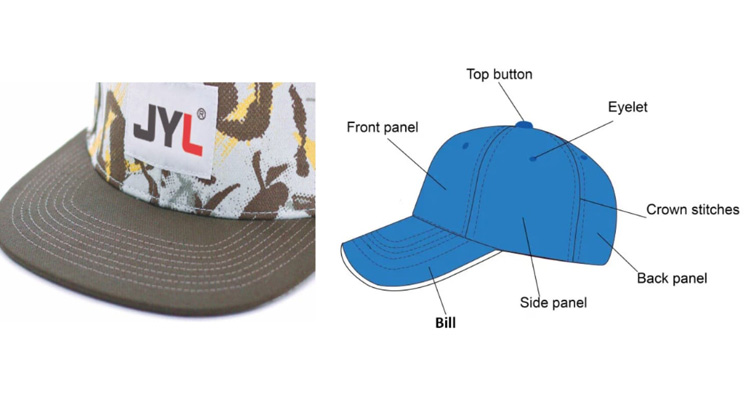

Sewing Machine for Hat Visors: This could refer to a regular sewing machine used for sewing hat visors onto hats. Hat visors are the stiff, protruding part of a hat's brim that shields the eyes from the sun. To sew a hat visor onto a hat, you would typically use a Hat Visor Sewing Machine with appropriate settings and stitches suitable for the materials involved.

Industrial Sewing Machine for Hat Visors: In some manufacturing settings, especially in the hat-making industry, there might be specialized sewing machines designed specifically for sewing hat visors onto hats in a production line. These industrial sewing machines are optimized for speed and efficiency.

FAQ – Double Station Caps Visor Sewing Machine

1. What materials can this sewing machine handle?

This machine is capable of sewing through a wide range of materials commonly used in hat visors and shoe uppers, including canvas, cotton, synthetic fabric, leather, EVA, and foam-backed composites.

2. Is this machine suitable for curved visor stitching?

Yes, the machine is specially designed for curved surface sewing, making it ideal for hat visors (such as baseball caps and snapbacks) that require precise and consistent seam lines on curved brims.

3. Can it operate continuously for mass production?

Absolutely. With its double station structure, this machine supports alternate sewing and loading operations, maximizing productivity and minimizing idle time—perfect for batch production lines.

4. What happens if a thread breaks or a needle breaks during operation?

The machine is equipped with automatic broken thread and needle detection. Once a break is detected, the system will alarm and stop automatically, ensuring safety and preventing further material damage.

5. Is there an automatic thread winding feature?

Yes, the machine uses electronic winding technology to control the thread amount precisely. This improves efficiency and consistency while reducing manual adjustment time.

6. Does it require compressed air to operate?

Yes, the machine requires a stable air supply of 0.6 Mpa (1.8L/min) for smooth operation. There is also an air pressure alarm that notifies the operator if the pressure drops below 0.4 Mpa.