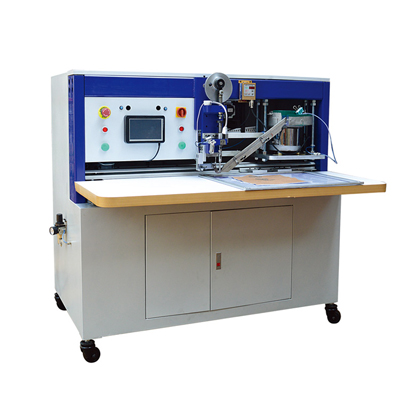

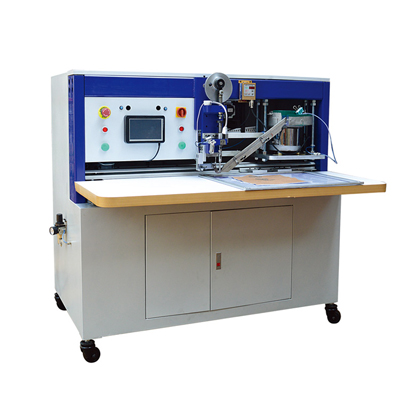

Automatic Button Machines are valuable tools used in the apparel and textile industry to efficiently attach buttons onto garments. To ensure their longevity and optimal performance, regular maintenance is crucial. After each use, it is important to remove any debris, fabric fibers, or button remnants that may have accumulated on the machine. A soft brush or compressed air can be used to clean the button feeder, presser foot, and needle area. Additionally, it is recommended to wipe down the machine with a clean, dry cloth to remove any dust or residue.

Proper lubrication is vital for the smooth movement of the machine parts. Consult the machine's manual for specific lubrication points and use a high-quality Sewing Machine oil or lubricant. Apply oil to the recommended areas, such as the pivot points and moving parts, to reduce friction and ensure smooth operation.

Regularly inspect and replace the needles and button feeders. Needles can become dull or damaged over time, leading to issues such as skipped stitches or button attachment problems. It is important to replace the needles according to the manufacturer's recommendations. Similarly, worn or damaged button feeders should be replaced promptly to ensure precise and consistent button attachment.

Check the electrical components and wiring regularly to ensure they are in good condition. Inspect the power cord and plug for any signs of damage, and replace them if necessary to prevent electrical hazards. Additionally, keep the machine's electrical components clean and free from dust or debris.

In conclusion, maintaining automatic Button Machines is vital to ensure their optimal performance and longevity. Regular cleaning, proper lubrication, needle and button feeder replacement, inspection of electrical components, and professional servicing are key maintenance practices. Following these practices will help keep the machine in top condition, ensuring efficient and accurate button attachment for garment production.