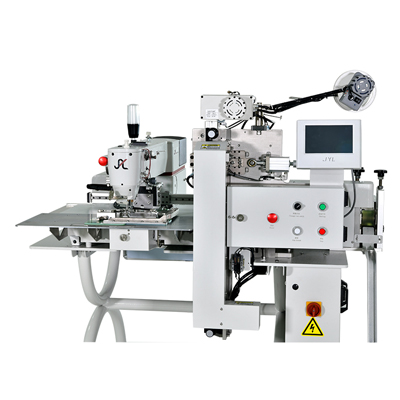

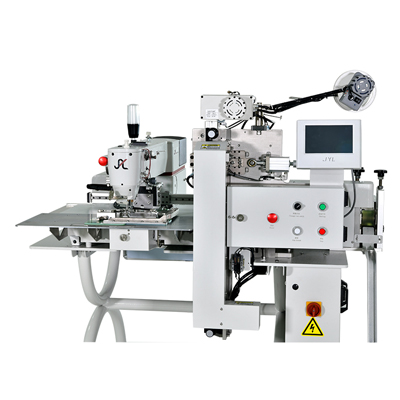

An eyelet Punching Machine is a specialized tool used to create holes in materials and insert eyelets for reinforcement and decoration. It's commonly employed in industries such as apparel, footwear, leatherworking, and signage. The machine's usage involves several straightforward steps to achieve accurate and consistent eyelet placement.

Firstly, ensure that you have the necessary materials and eyelets ready for the process. The eyelet punching machine typically comes with different-sized dies to accommodate various eyelet sizes.

1. Preparation:

- Place the eyelet punching machine on a stable and flat surface, ensuring proper stability during operation.

- Select the appropriate die size that matches the eyelet diameter you intend to use.

2. Material Preparation:

- Mark the desired locations where you want to insert the eyelets on your material.

- Lay the material on the machine's work surface, aligning the marked holes with the die below.

3. Inserting Eyelets:

- Position the material under the punching head of the machine, aligning the marked hole with the center of the die.

- Lower the punching head gently to create a hole in the material. The die will cut through the material and create a clean hole.

4. Eyelet Placement:

- With the hole now created, place the eyelet through the hole from the front side of the material.

- The eyelet's flange (the wider, flat part) should be against the backside of the material.

5. Securing the Eyelet:

- Lift the punching head and align the anvil (a flat metal piece) over the protruding end of the eyelet.

- Gently lower the punching head again to press the eyelet's flange against the anvil. This action compresses the eyelet, securing it in place and creating a finished look.

6. Finishing:

- Lift the punching head and remove the material with the inserted eyelet from the machine.

- Repeat the process for the remaining holes and eyelets.

7. Quality Check:

- After attaching all the eyelets, inspect the finished product to ensure proper alignment, secure attachment, and overall quality.

Keep in mind that while the general steps are straightforward, it's essential to follow the manufacturer's guidelines and safety instructions provided with the eyelet punching machine. Different machines might have variations in design and operation. As with any machinery, wear appropriate safety gear, such as safety glasses, to protect yourself during operation.