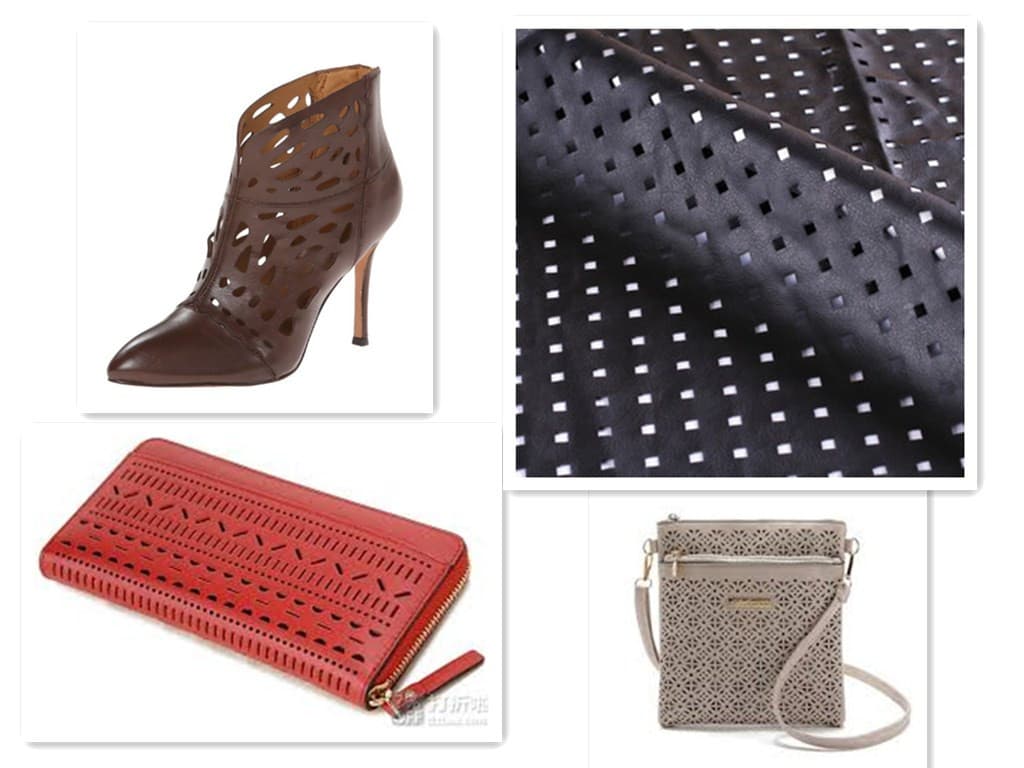

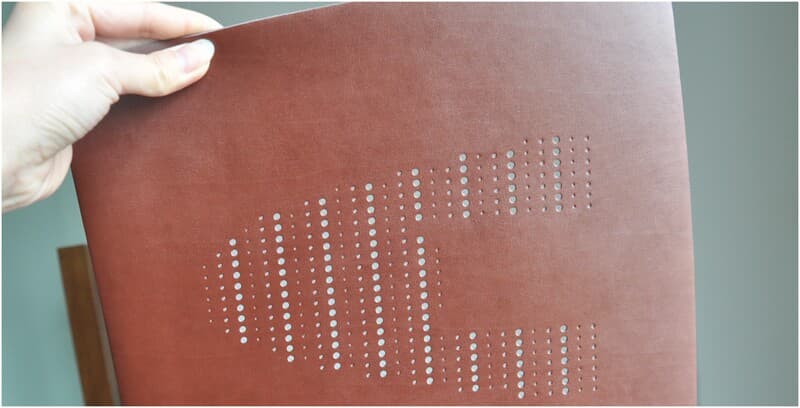

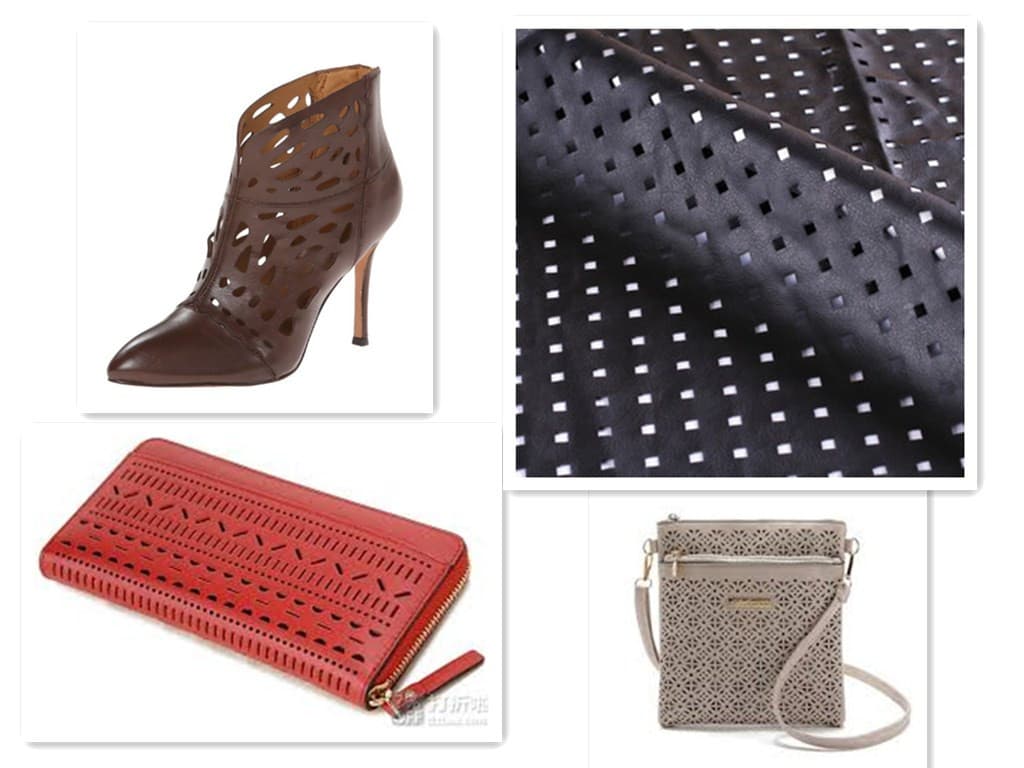

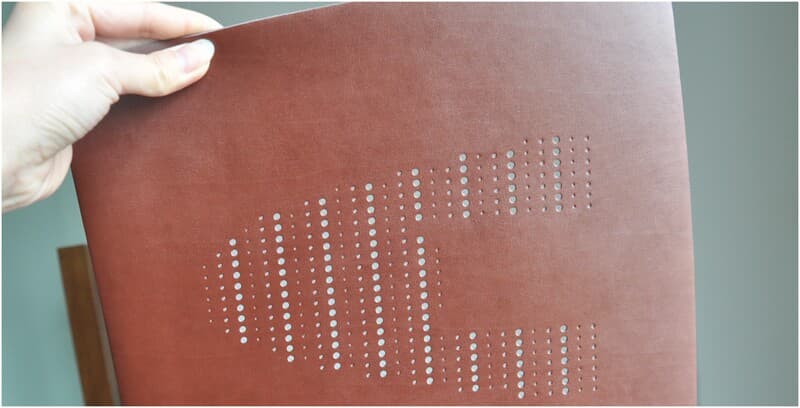

cnc leather punching machines are sometimes referred to as HANDBAG-Punching Machine as well as leather punching machine upper punching machine/shoe vamp car seat punching machine and suitcase punching machines, etc. It is a combination between CNC and software techniques. It offers many advantages such as high efficiency, speedy speed No blackening, there is no smell, no burning. This machine that punches automatically can be used in these fields automobile accessories (breathable cushion) bags, suitcases, suitcases handbags, stationery, footwear made of leather, breathable materials furniture, advertising items, and various other industries. It is suitable for the following materials including sheep and cow leather, artificial leather EVA, PU PVC, plastics, different fabrics, papers and leather accessories, curtains cars with leather seats mouse pads, etc.

Product Specification

| Item No. | JYL-A5-1 |

| Working Area | 600× 500mm |

| Speed | 420-1100PCS/min |

| Voltage | 110V-240V |

| Pressure | 5-6KG/cm2 |

| Product size | 1800 ×1500× 1510mm |

Main Features

speeds of leather punching machine is up to 420-1100 pcs /min.

Automatic punching machine made with JYL multi-axis CNC system, can installed 5 kinds of punch needles

Japan Fuji motor power

Large working area which is 600 * 500mm.

Can produce various patterns on the leather due to the adjustable angle of needles.

Can pouch complex patterns on the small area.

Lower noise, good quality of the hole, wouldn't burn compared to the laser-beam drilling machine

Easy to operate.

JYL-A5-2 Double head working stations , High efficiency. for mass production line.

Streamlining Production with Automated CNC Punching Machines

In today's rapidly evolving manufacturing landscape, efficiency and precision are paramount. One technology that has revolutionized metal fabrication processes is the Automated CNC Punching Machine. These sophisticated machines integrate cutting-edge automation and computer numerical control (CNC) technology to streamline production and enhance productivity across various industries.

Automated CNC Punching Machines are engineered to optimize the punching process for sheet metal fabrication. With their advanced capabilities, they enable manufacturers to achieve unparalleled levels of accuracy and efficiency in punching operations. These machines are equipped with precise tooling systems and sophisticated control software, allowing for the rapid and precise execution of complex punching tasks.

One of the key advantages of Automated CNC Punching Machines is their ability to automate repetitive tasks. By programming the machine with the desired punching patterns and specifications, manufacturers can significantly reduce manual intervention and minimize the risk of errors. This not only speeds up the production process but also ensures consistency and repeatability in the finished products.

Moreover, Automated CNC Punching Machines offer unmatched versatility in terms of the types of materials they can process and the variety of punching operations they can perform. Whether it's creating holes, slots, or intricate patterns, these machines can handle a wide range of punching tasks with ease. This flexibility makes them indispensable tools for manufacturers working with diverse materials and product designs.

Another key feature of Automated CNC Punching Machines is their integration with CAD/CAM software systems. This allows manufacturers to design complex punching patterns digitally and seamlessly transfer them to the machine for execution. By leveraging the power of CAD/CAM integration, manufacturers can streamline the entire production workflow, from design to manufacturing, reducing lead times and improving overall efficiency.

Furthermore, Automated CNC Punching Machines contribute to cost savings and resource optimization in manufacturing operations. By minimizing material waste and maximizing production throughput, these machines help manufacturers achieve higher levels of productivity while reducing operating costs. Additionally, their ability to operate continuously with minimal downtime ensures optimal utilization of resources and manpower.

In addition to their technical capabilities, Automated CNC Punching Machines also offer ergonomic benefits for operators. Modern machines are equipped with user-friendly interfaces and intuitive controls, making them easy to operate and maintain. This not only improves operator efficiency but also enhances safety in the workplace, reducing the risk of accidents and injuries.

The impact of Automated CNC Punching Machines extends beyond individual manufacturing facilities to the broader manufacturing ecosystem. By enabling faster turnaround times and higher production volumes, these machines support just-in-time manufacturing practices and enable manufacturers to respond quickly to changing market demands. This agility is crucial in today's competitive marketplace, where speed and flexibility are essential for success.

In conclusion, Automated CNC Punching Machines represent a significant advancement in metal fabrication technology, offering manufacturers a powerful tool for streamlining production and enhancing efficiency. With their advanced automation capabilities, versatility, and integration with digital design systems, these machines are driving innovation and transforming the manufacturing industry. As manufacturers continue to embrace automation and digitalization, Automated CNC Punching Machines will play an increasingly vital role in shaping the future of manufacturing.