Introduction to Automatic Riveting Machine

An Automatic Riveting Machine is a highly efficient and precise industrial device designed to automatically insert rivets into materials during the manufacturing process. This machine is widely used across various industries, especially in the production of leather goods such as belts, bags, and shoes.

Application in Belt Production

In belt production, the primary function of an Automatic Riveting Machine is to accurately install metal rivets into leather belts to secure buckles or other decorative elements. The use of this machine significantly enhances production efficiency and ensures uniformity in the placement and quality of the rivets.

Key Features

1.High Efficiency: The automatic riveting machine can perform continuous riveting operations much faster than manual methods, making it ideal for mass production.

2.High Precision: The machine can precisely control the placement and depth of the rivets, ensuring that each rivet is installed to meet standards, thereby reducing human error.

3.Ease of Operation: Equipped with intelligent control systems, automatic riveting machines require minimal training for operators, reducing the skill level needed for operation.

4.Wide Applicability: Besides leather products, the machine can also be used for riveting other materials such as plastics and fabrics.

5.Stability and Durability: The machine is built with robust construction, offering stable performance and low maintenance costs, capable of long-term continuous operation.

Working Principle

An automatic riveting machine uses an automatic feeding system to deliver rivets to the designated position, followed by a pressure system that presses the rivet into the leather. This entire process is controlled by a pre-set program, ensuring each rivet is accurately and flawlessly installed on the belt.

Operating Steps

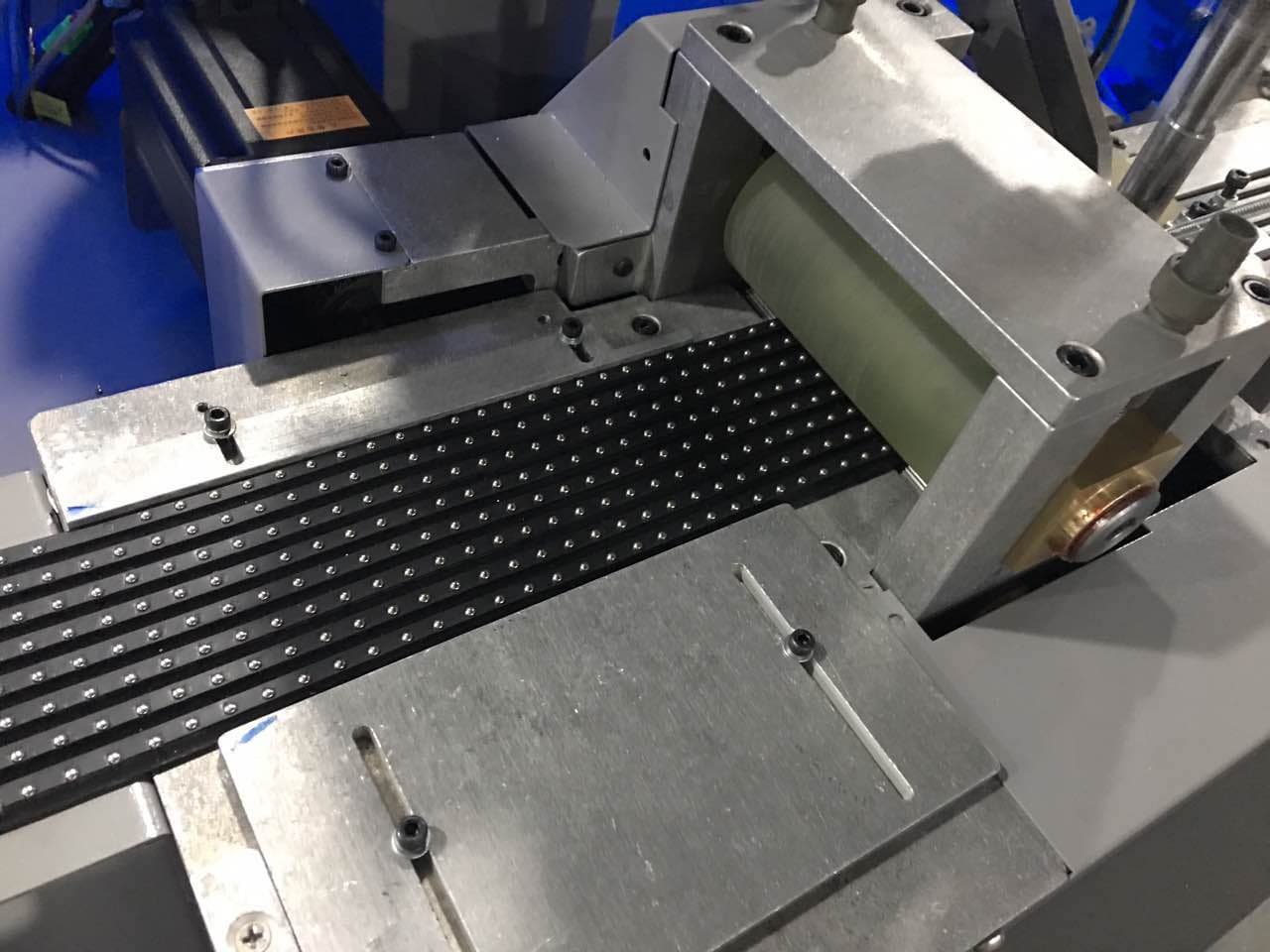

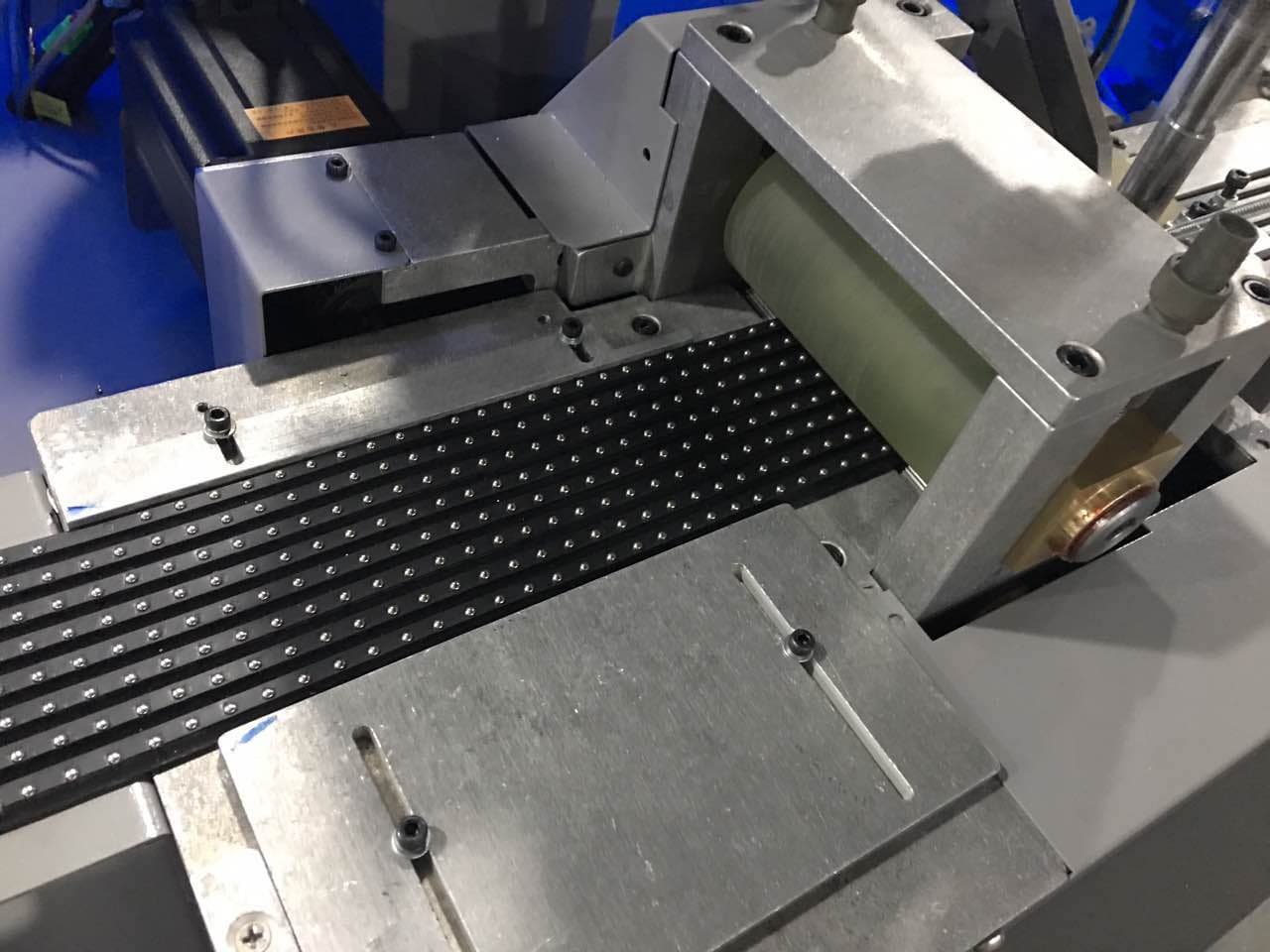

1.Preparation: Place the leather belt that needs riveting on the machine’s working table and adjust the machine settings to match the belt’s thickness and the size of the rivets.

2.Automatic Feeding: The machine automatically feeds the rivets through the feeding system to the riveting head.

3.Riveting Installation: Start the machine via the control system, and the riveting head presses the rivets into the belt, completing the installation.

4.Inspection and Adjustment: After a batch of riveting is completed, check the quality and position of the rivets on the belt. Make adjustments if necessary.

An automatic riveting machine is an indispensable piece of equipment in the belt manufacturing process. It not only increases production efficiency and product quality but also reduces production costs. For any leather goods manufacturer looking to enhance production capacity and product consistency, an automatic riveting machine is an ideal choice.

Industrial Automatic Computerized Riveting Machine for Leather Belts

This Automatic belt nail Attaching Machine is suitable for round nails with a diameter of 210mm as well as square claws that measure 4x10mm. Its working speed, fixed strength, and brightness can be changed. It is easy to operate for workers. It is safe to use and easy to adjust. The machine's programming can be done by computer using special program that is included with the machine, or by the import of dxf file files created with other programs. Full automatic feeder, as the thickness of the material increases the machine automatically adjusts the strength of pressure. It is stable in performance, precise positioning and high efficiency features.

Product Specification

| Item No. | JYL-A6-L |

| Working Area | X:Unlimited length |

| Y:100mm |

| Speed | 70-100PCS/min |

| Voltage | 110V-220V |

| Pressure | 5-6KG/cm2 |

| Nails size | (Round)2.0-10.0mm |

| (Square)4.0-9.0mm |

| Product size | 800 ×800× 1300mm

|

Product Description

This Computerized Belt Nails Riveting Machine is suitable widely used for rivets/nails decoration on shoes, bags, belts, jeans and suitcases, sofa furniture, etc. Suitable for 2~10mm diameter round nails and square four claw nails in 4~10mm.

Product Features

1.Suitable for 2~10mm diameter round nails and square four claw nails in 4~10mm.

2.Working speed,fixed strength,brightness can be adjusted

3.Easy operable. safe use and convenient adjustment.

4.The machine programming can be achieved by computer with a special software supplied along with the machine or by importing dxf files created by other softwares.

5.Full automatically feeder, when the material thickness become thicker, it automatically turns to the pressure strength.

6.Stable performance,Precise positioning,High efficiency.

Automatic Riveter:

An automatic riveter is a sophisticated industrial tool designed to streamline the process of attaching rivets to various materials. It operates with precision, speed, and consistency, making it a valuable asset in manufacturing and assembly lines. Equipped with programmable settings, it can adapt to different rivet sizes and materials, ensuring accurate and secure fastening. The automatic riveter enhances efficiency by reducing manual labor and minimizing errors. Its automation capabilities contribute to higher production rates and improved product quality across industries like automotive, aerospace, and construction.

Auto Riveting Machine:

An auto riveting machine is a highly efficient industrial device used for automating the process of fastening rivets in various applications. It features programmable controls that allow it to work with different rivet sizes, materials, and configurations. This machine significantly increases production speed and accuracy by eliminating the need for manual riveting. It's widely utilized in industries such as automotive, electronics, and aerospace, where precise and secure rivet connections are crucial. The auto riveting machine enhances overall productivity, reduces labor costs, and ensures consistent and reliable rivet installation, making it an essential tool for modern manufacturing processes.

Semi Automatic Riveting Machine:

A semi-automatic riveting machine is a versatile industrial tool designed to streamline the riveting process while allowing some manual input. It combines automated rivet placement and compression with human-operated component loading. This setup provides a balance between efficiency and operator control. The machine offers adjustable settings for rivet size, pressure, and cycle speed, accommodating various applications. It enhances productivity by reducing the physical effort needed for riveting, making it ideal for small to medium production volumes. The semi-automatic riveting machine finds use in industries like electronics, leather goods, and metal fabrication, where precise and consistent riveting is essential.