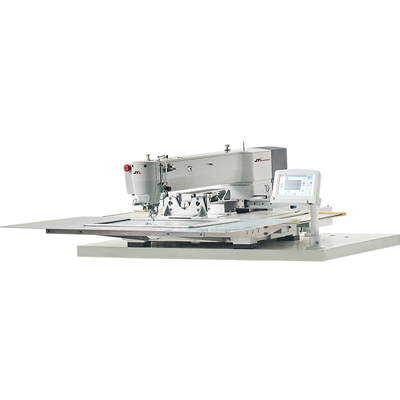

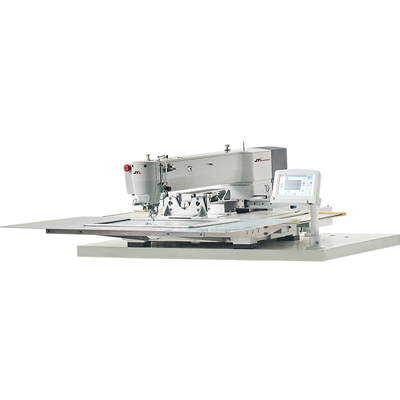

Programmable Sewing Machines are powerful tools that significantly enhance sewing efficiency and creativity. However, like any mechanical device, they require regular maintenance to ensure optimal performance and longevity. Proper care not only helps prevent mechanical issues but also enhances the machine's reliability and the quality of the finished products. Here are essential maintenance tips to keep your programmable Sewing Machine in excellent condition.

1. Regular Cleaning

One of the most important maintenance tasks is keeping the machine clean. Dust and lint can accumulate in various parts of the sewing machine, affecting its performance.

Clean the Bobbin Area: Remove the bobbin case and clean out any lint or thread remnants using a soft brush or a vacuum attachment. This area should be cleaned regularly, especially after extensive sewing sessions.

Wipe the Exterior: Use a soft, damp cloth to wipe the machine's exterior. Avoid using harsh chemicals or solvents that could damage the surface.

2. Oil the Machine

Lubrication is essential for smooth operation. Consult your machine’s manual to determine the appropriate lubrication points and the type of oil recommended.

Use Sewing Machine Oil: Apply a few drops of oil to the designated lubrication points as indicated in the manual. Be careful not to over-oil, as excess oil can attract dust and lint.

Frequency: Perform this maintenance task regularly, typically after every 10 hours of sewing or as recommended by the manufacturer.

3. Check and Change the Needle

A sharp, appropriate needle is crucial for clean stitching. Using a dull or damaged needle can lead to skipped stitches and fabric damage.

Inspect the Needle: Check the needle for any signs of wear or bending before starting a project. If you notice any issues, replace it immediately.

Use the Right Needle: Choose the correct needle type and size based on the fabric you are working with. For instance, use a universal needle for woven fabrics and a ballpoint needle for knits.

4. Maintain the Thread Tension

Proper thread tension is vital for achieving quality stitches. If the tension is too loose or too tight, it can lead to sewing problems.

Regularly Check Tension Settings: Refer to the machine's manual for recommended tension settings for different fabrics and stitch types. Adjust the tension as needed during sewing.

Use Quality Threads: High-quality threads can help maintain consistent tension and reduce the risk of breakage or tangling.

5. Update Software and Firmware

Many programmable sewing machines come equipped with digital features that may require software updates.

Check for Updates: Periodically check the manufacturer's website for any available software or firmware updates that can enhance your machine's functionality.

Follow Instructions: Follow the manufacturer’s guidelines for updating the machine to ensure a smooth process.

6. Store Properly

How you store your sewing machine can affect its longevity.

Cover the Machine: When not in use, cover your sewing machine with a dust cover to protect it from dust and debris.

Store in a Controlled Environment: Avoid exposing the machine to extreme temperatures or humidity, which can affect its mechanical components.

7. Regularly Test Stitches

Testing stitches regularly can help identify potential issues before they become significant problems.

Sew Test Fabrics: Before starting a new project, sew on scrap fabric to check for stitch quality and tension settings.

Adjust Settings as Needed: Make any necessary adjustments based on the test results to ensure optimal performance.

8. Seek Professional Servicing

Even with regular maintenance, your machine may require professional servicing to address specific issues.

Schedule Regular Check-ups: Consider taking your sewing machine to a certified technician for a thorough inspection and servicing at least once a year.

Identify Problems Early: Regular servicing can help catch and fix problems early, preventing costly repairs later on.

By following these maintenance tips, you can ensure your programmable sewing machine remains in top working condition, providing you with high-quality results for years to come. Regular cleaning, lubrication, and inspections will enhance its performance and extend its lifespan, allowing you to focus on your creativity without interruption. Remember, investing time in maintenance pays off in the long run, ensuring that your sewing projects are both enjoyable and successful.