Sewing Machines for caps, often referred to as cap or Hat Sewing Machines, are specialized tools designed for the unique requirements of cap construction. These machines are engineered to handle the intricate stitching required for creating high-quality, durable caps, such as baseball hats or other headwear. One common question when considering a Cap Sewing Machine is whether it can sew both the crown and the brim of a cap. Let's explore how these machines function and how they handle different parts of cap production.

The Crown of the Cap:

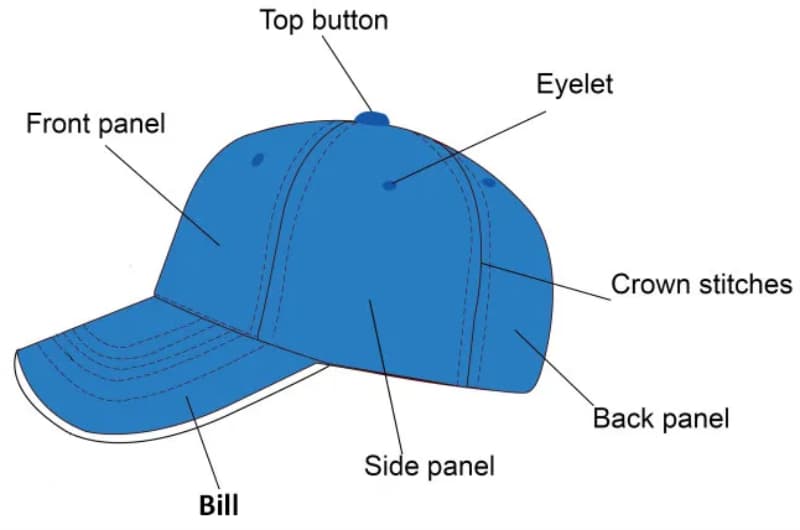

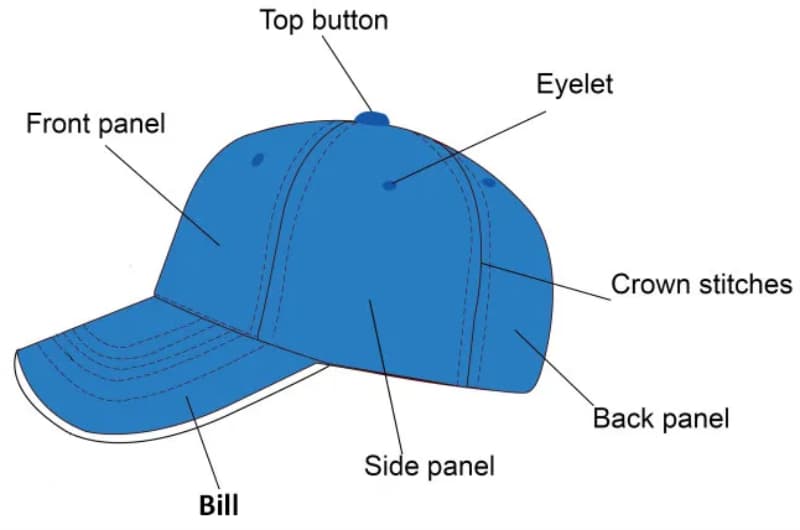

The crown of a cap refers to the main top portion, which typically consists of several panels of fabric stitched together to form the desired shape. This section requires precision stitching to ensure a snug and comfortable fit. Cap sewing machines are designed with a specialized, adjustable sewing head that allows for stitching along the curved seams of the crown. These machines are equipped with curved needle bars and can handle the multi-layered, often thick fabric that makes up the crown.

A cap sewing machine’s ability to sew the crown is one of its key features. With the right setup, these machines can easily stitch multiple panels together with consistent tension and stitch quality, which is crucial for both aesthetics and durability. The advanced features of cap sewing machines, such as adjustable presser feet, automatic thread trimming, and specialized stitch patterns, make them perfect for sewing the crown of the cap.

The Brim of the Cap:

The brim, or bill, of the cap is another critical part of its design. This is the stiffened portion that extends outward from the crown, often made from a different material such as cardboard, plastic, or foam for structure. The brim of a cap is generally sewn onto the crown, and this requires both accuracy and strength to ensure the brim stays securely attached.

While regular sewing machines might struggle to sew through the rigid brim material, sewing machines for caps are specifically designed to handle this task. Many of these machines feature adjustable feet or specialized attachments that help accommodate the flat, stiff nature of the brim. Additionally, cap sewing machines typically have stronger motors and better feed mechanisms, allowing them to sew through multiple layers of fabric as well as the stiffer materials commonly used for the brim.

Can a Cap Sewing Machine Sew Both the Crown and the Brim?

Yes, sewing machines designed for caps can sew both the crown and the brim of a cap. However, the process involves different techniques and equipment to handle the different materials and shapes of each part.

For the crown, cap sewing machines use their curved sewing arms and adjustable feet to stitch through multiple layers of fabric. This is an important feature, as the crown can often involve several panels that need to be stitched with precision and care. The sewing machine’s ability to move smoothly around these panels ensures the finished cap has a clean and professional look.

For the brim, cap sewing machines often utilize specialized attachments, such as flatbed extensions or custom presser feet, to help sew through the stiffer materials that make up the brim. The machine’s heavy-duty construction ensures it can handle the additional thickness and stiffness of the brim material while still providing consistent stitching quality.

Features That Facilitate Sewing Both the Crown and the Brim:

Adjustable Stitch Length and Tension:Cap sewing machines come with adjustable stitch length and tension settings that allow for versatility. When sewing the crown, these settings ensure a smooth, consistent stitch, while for the brim, they can be adjusted to account for the thicker, stiffer material.

Specialized Attachments and Presser Feet:These machines often come with a variety of attachments or presser feet that make it easier to sew around the curved crown or the flat brim. The ability to change feet according to the task ensures that the machine performs optimally for both parts of the cap.

Heavy-Duty Motor:A heavy-duty motor is essential when sewing through thicker fabrics and stiff brims. Cap sewing machines are equipped with motors powerful enough to handle the tougher materials typically used for caps while still producing a fine, consistent stitch.

Flatbed and Curved Arm Design:Cap sewing machines are designed with a flatbed for sewing the brim and a curved arm for sewing the crown. This dual functionality makes it possible for the machine to perform both tasks with ease.

Sewing machines for caps are specifically designed to handle the complexities of cap production, making it possible to sew both the crown and the brim with precision and efficiency. While these tasks involve different sewing techniques and equipment, the specialized features of cap sewing machines make them versatile enough to manage both the soft, curved crown and the stiff, flat brim. If you are in the business of producing caps, investing in a Sewing Machine For Caps is essential for achieving the quality, durability, and professionalism needed to create top-notch headwear. Whether for commercial use or for personal projects, these machines offer a reliable solution to handle the full cap construction process.