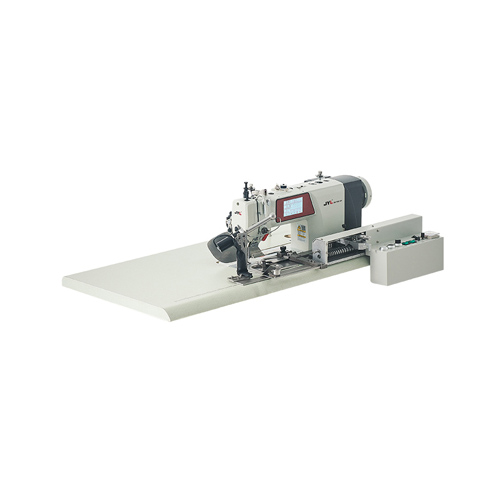

In the fast-paced world of hat manufacturing, efficiency, precision, and quality are key factors in staying competitive. The Bucket Hat Sewing Machine has been designed to address these challenges, offering several advanced features that significantly improve the production process. In this article, we will explore some of the innovative features that make this machine a game-changer for hat factories and manufacturers.

1. Automatic Needle Setting

One of the standout features of the Bucket Hat Sewing Machine is its automatic needle setting function. This feature eliminates the need for manual adjustments, which can be time-consuming and prone to human error. With automatic needle setting, the machine adjusts the needle position based on the specific pattern or fabric being used. This enhances the speed of production and ensures uniform stitching, which is especially important when creating complex patterns or stitching the brim of bucket hats.

The automatic needle setting also allows the operator to focus on other tasks, reducing the amount of time spent on manual adjustments and improving overall productivity. This feature is ideal for manufacturers looking to streamline their operations and reduce labor costs while maintaining high-quality standards.

2. Thread Clamping Function

Thread clamping is another key feature that enhances the performance of the Bucket Hat Sewing Machine. The thread clamping function ensures that the thread is held securely during the sewing process, preventing it from loosening or tangling. This is particularly important when working with materials that can be prone to fraying or slipping, such as lightweight fabrics or materials with a slippery texture.

By ensuring that the thread is tightly secured, the machine reduces the risk of skipped stitches or uneven sewing, resulting in a more consistent and high-quality finished product. This feature also helps to maintain the integrity of the fabric, especially during high-speed stitching, where there is a higher risk of thread breakage or movement.

3. Breakage Needle Detection

Another invaluable feature of the Bucket Hat Sewing Machine is its breakage needle detection system. In a high-speed manufacturing environment, needle breakage can lead to production delays, material wastage, and costly repairs. With the breakage needle detection feature, the machine automatically detects if a needle has broken or become damaged during the stitching process.

When the system identifies a problem, it alerts the operator immediately, allowing for quick resolution before significant damage is done. This feature ensures that production continues smoothly without the risk of defective stitching or machine malfunction. Additionally, it prevents unnecessary downtime and ensures that the machine remains operational, maximizing production output.

4. User-Friendly Touchscreen Control

The Bucket Hat Sewing Machine is equipped with a 7.5-inch LCD touchscreen control panel, which makes it easy to operate and adjust the settings. The intuitive interface allows users to quickly edit stitching patterns, adjust needle positions, and fine-tune other settings, making it simple even for novice operators to use the machine with ease.

The touchscreen control also offers a range of customization options, allowing users to store up to 999 different patterns, making it easy to switch between various hat designs without the need for reprogramming. This flexibility is especially beneficial for manufacturers who produce a variety of hat styles, as they can quickly adjust the settings to meet different requirements.

5. High-Speed Sewing

The Bucket Hat Sewing Machine is designed for high-speed operation, with a sewing speed of up to 3000 rpm. This speed is crucial for manufacturers looking to meet the demands of mass production while maintaining precision and quality. The ability to sew quickly without compromising on stitch quality allows factories to significantly increase their output, reducing lead times and meeting tight deadlines.

6. Versatility for Multiple Hat Types

The Bucket Hat Sewing Machine is not limited to bucket hats alone. Its versatile design allows it to handle a wide range of hat types, including fisherman hats, Irish county hats, and boonie hats. This flexibility makes the machine a valuable investment for manufacturers who produce various styles of headwear. By utilizing the same machine for multiple hat types, manufacturers can reduce their equipment costs while maintaining the same level of efficiency and quality.

7. Durability and Stability

Built with Japan-imported machine heads, the Bucket Hat Sewing Machine offers unmatched stability and durability. The machine is designed to withstand high-speed operation and the rigors of continuous use in a manufacturing environment. This reliability minimizes downtime due to machine malfunctions and ensures that the machine remains operational for long periods, providing a great return on investment for manufacturers.

The innovative features of the Bucket Hat Sewing Machine make it an essential tool for modern hat manufacturers. With automatic needle setting, thread clamping, breakage needle detection, and high-speed sewing capabilities, this machine offers efficiency, precision, and durability that are unmatched in the industry. Whether you're producing bucket hats, fisherman hats, or other headwear, the Bucket Hat Sewing Machine helps streamline the production process while ensuring the highest quality standards. Investing in this advanced machine can lead to significant improvements in productivity, cost-efficiency, and product quality, making it an indispensable asset for any hat production facility.