In the process of using the Jeans Sewing Machine to sew clothing, sometimes the speed of the clothing is not uniform, and the stitches are long and short. Clothing material moves forward by the cooperation of feeding teeth and presser foot. Therefore, when the above-mentioned irregular movement occurs in the clothing material, it can be concluded that the teeth and presser foot have malfunctioned or the pressure is not adjusted properly. For example, the presser foot pressure is too low. If the fabric is not pressed tightly, it will cause irregular movement. At this time, just turn the pressure adjusting screw downward to compress the clothing material. If the presser foot is too high, it will not be able to press the material, and it will also cause the material to move randomly or not at all. When adjusting, first lift the presser foot wrench, loosen the screw of the guide frame, and then move the presser foot lever from top to bottom, so that After adjusting the distance between the presser foot and the needle plate to a height of 7-8 mm, tighten the screws immediately before driving.

Another reason is that the tooth screws are loose, causing the teeth to shake from side to side during operation, so that the clothing cannot move forward regularly. The solution is to remove the needle plate. Tighten the two tooth screws. After tightening, install the needle plate and check whether the two sides of the teeth rub against the edge of the needle plate groove. If there is friction, it will cause noise and machine weight. At this time, only remove the needle plate and loosen the teeth screws. Adjust the tooth position to the middle of the needle plate groove, tighten the tooth screws, and then install the needle plate.

The movement of the cloth is entirely carried by the teeth. When it turns out that the fabric doesn't move at all, it's only the teeth that are the problem. If the teeth are set too low, it is impossible for the material to move forward. When adjusting, first turn the head of the machine, loosen the screw of the tooth lifting crank, and then gently lift the tooth frame with a screwdriver to make the cloth feeding tooth direction. It is enough to expose the needle plate 0.8-1 mm above. It is the standard size of the height of the teeth. As long as it is adjusted to this position, the cloth can move normally.

When using the Sweatband Sewing Machine to sew clothes, the clothes often move back and forth, that is, one step forward and one step back. This is caused by the fact that the feed teeth are too high, the plane where the teeth are exposed to the needle plate is too high, and the teeth are always exposed outside the needle plate and move back and forth, causing the cloth to move back and forth. When adjusting, loosen the tooth lift crank screw, press down the tooth with a screwdriver to lower the feed dog to the standard height, that is, the tooth is exposed to the size of 0.8-1 mm from the needle plate, and then tighten the crank screw.

Sometimes in the sewing work, the cloth does not move forward, but moves toward the operator, that is, the cloth moves backward. This failure is due to the wrong angle between the upper shaft crank throw and the cam eccentric screw. The teeth can move forward rhythmically. It depends entirely on the movement of the cloth feeding cam. Because the cam itself is eccentric. Therefore, the tooth fork is moved back and forth, and the tooth fork drives the cloth feeding shaft and the tooth frame to promote the reciprocating movement of the teeth back and forth. It can be seen that the eccentric position of the cam is very important.

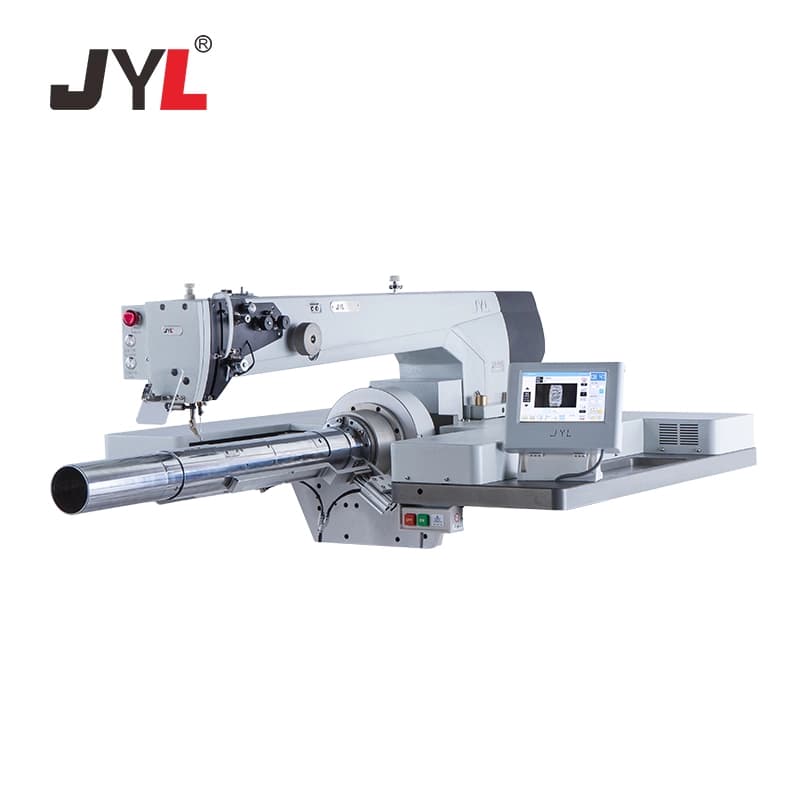

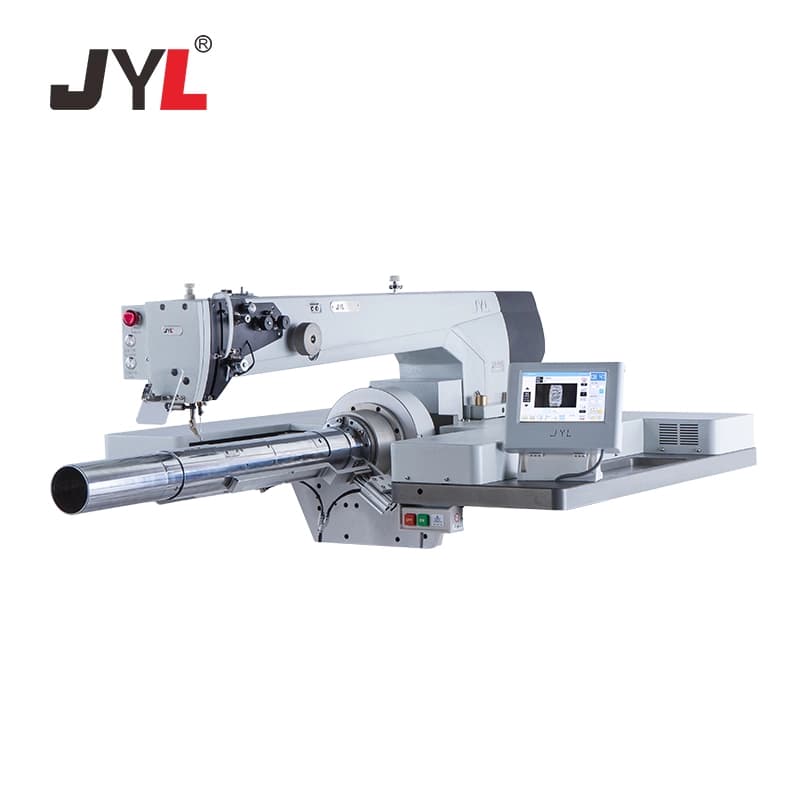

Apart from that, we also have Shoes Sewing Machine for sale, high quality production, years of experience and more.