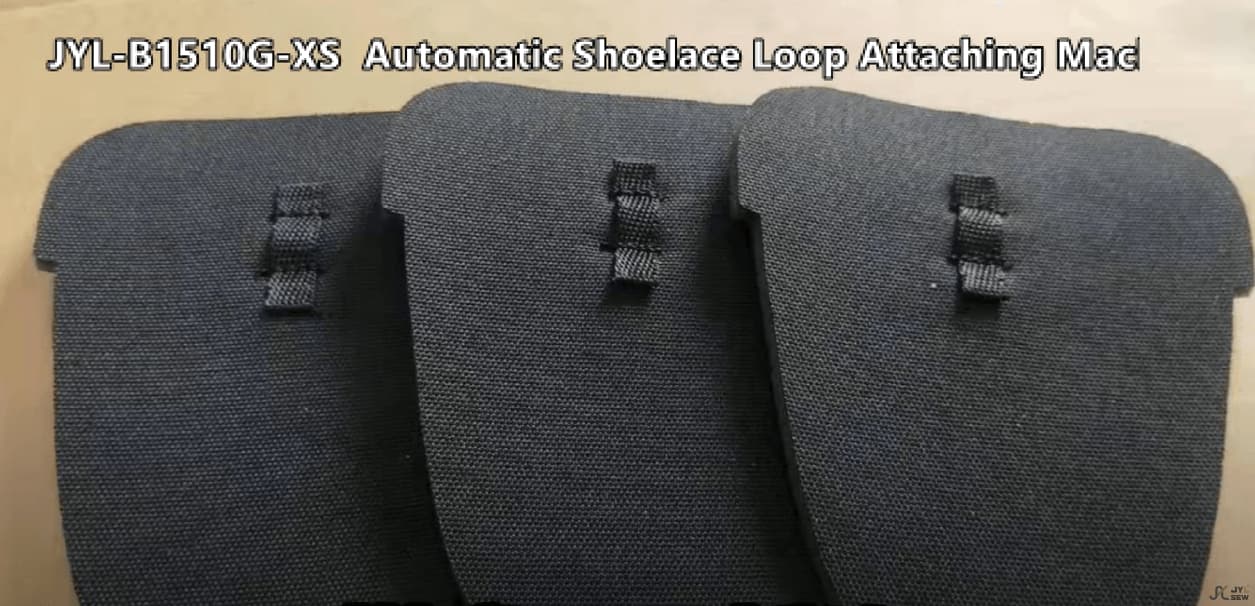

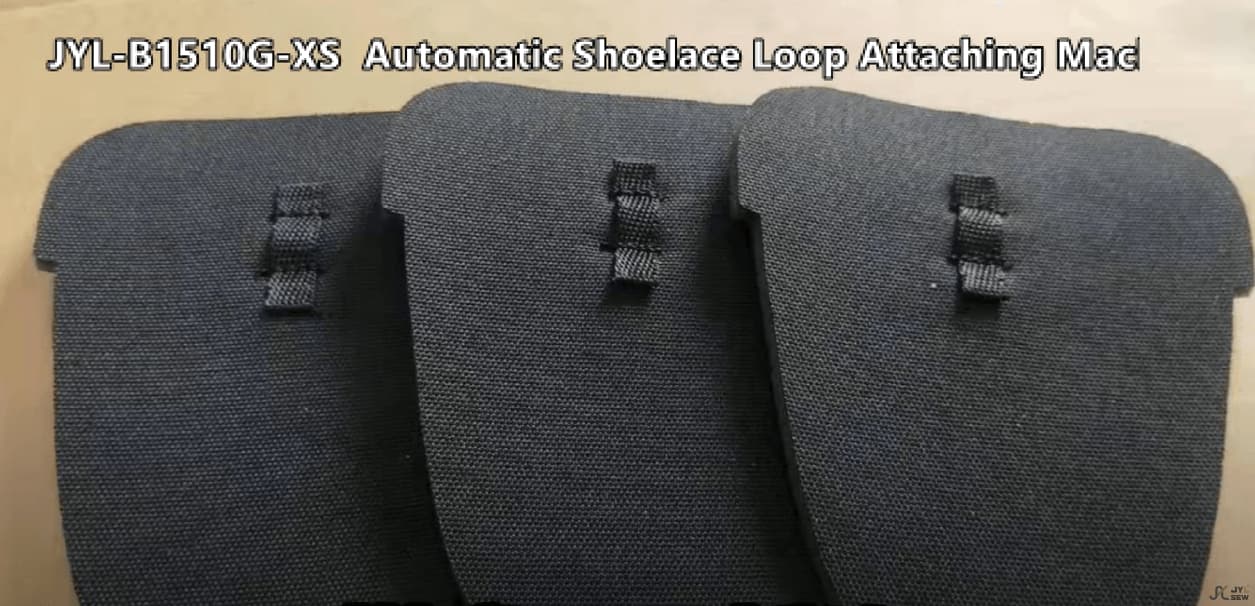

Shoelace loop attaching sewing machine with the mechanical arm to feed the shoelace, safe production, reduce the operation accident. Compare to the traditional old sewing machine, this new machine improve at least 60% working efficiency. One worker can operate the several loop attaching sewing machines, improve the production efficiency. This automatic computerized industrial sewing machines is suitable for stitching various surface fabric, like men's /women's/denim/ knitwear/underwear/bags/shoes.

Product Specification

| Item No. | JYL-B1510G-XS |

| Sewing Area | 120x80mm |

| Maximum Sewing Speed | 2700r.p.m |

| Sewing Trace | Single Needle Flat Seam |

| Feeding | Intermittent feeding(Pulse motor drive mode) |

| Intermittent pressure foot lift | 17mm |

| Hook | Shuttle hook |

| Presser foot lifting mode | Pulse motor drive mode |

| Motor | AC servo motor 750W direct drive |

| Air pressure | 0.5MPa 1.8L/min |

| Power supply | Single-phase 220V |

| Machine Size | 1320×1000×1280MM |

| Weight | 210KG

|

Product Features

1.High performance sewing:The tongue ring sewing machine adopts advanced sewing technology with high sewing speed and stability, which can complete a large number of sewing tasks in a short time and greatly improve the production efficiency.

2.Automatic control:Equipped with intelligent control system, it can automatically adjust sewing parameters, such as sewing speed, stitch length and thread tension, etc. to ensure that every stitch achieves the best result.

3. Accurate Sewing:The machine adopts high-precision sewing head to ensure the accuracy of sewing, and can handle various complicated sewing patterns to ensure the quality and appearance of the shoe tongue.

4. Human-machine interface:The machine is equipped with an easy-to-operate touch screen interface, which allows the operator to easily set and adjust the sewing parameters and monitor the production status in real time, which is convenient and quick.

5 Durability and Reliability:Made of high quality materials with strong wear resistance and stability, it can operate for a long time in a high intensity working environment, reduce the failure rate and extend the service life of the equipment.

6. Multifunctionality: This sewing machine is not only suitable for tongue ring sewing, but also for sewing other footwear parts, which meets a variety of production needs and improves the applicability of the equipment.

Fields of application

1. Sports shoes manufacturing: Used for sewing tongue rings on sports shoes to ensure the fit and comfort of the shoes.

2. Leather shoes manufacturing: applied in the manufacturing of high-grade leather shoes to enhance the overall beauty and durability of the shoes.

3. Casual shoes and other types of footwear: widely used in the production of various shoe styles, improving production efficiency and finished product quality.

Main Features

Easy to operate, no need for skilled operators, reduce labor costs.

Mainly used in the processing of various footwear , it only takes 4 seconds to sew webbing ,significantly improve production efficiency.

Efficent and beautiful stitching improve the quality ,it is the preferred modle for the shoe webbing.

FAQ

What is a shoe tongue loop sewing machine?

What types of shoes can be manufactured using this machine?

What materials can be used with a shoe tongue loop sewing machine?

Common materials include leather, synthetic fabrics, nylon, and other durable textiles suitable for footwear.

What are the key features of a shoe tongue loop sewing machine?

How does the machine improve production efficiency?

What maintenance is required for this machine?

Can the machine be used for other sewing applications?

What are the safety features of a shoe tongue loop sewing machine?

What is the average production rate of a shoe tongue loop sewing machine?

Where can I purchase a shoe tongue loop sewing machine?