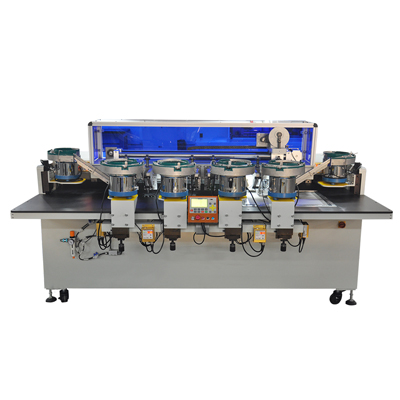

The Computerized Full Automatic Button Pressing Machine with Six Heads (Model: JYL-A6-6) is an advanced industrial button fastening solution designed for high-efficiency, large-scale production. This four-claw automatic upholstery button press machine supports a wide range of decorative rivets, snap buttons, and nails, making it ideal for use in garments, bags, belts, jeans, sofa furniture, and suitcases.

Its fully programmable system allows for the creation of complex button patterns with just one press operation, improving both production speed and accuracy while minimizing manual labor.

Computerized Multi-Pattern Programming

This industrial automatic button maker press machine can create various patterns based on pre-programmed software or by importing DXF files from third-party CAD programs.

Six-Head High-Speed Operation

Equipped with six working heads, the machine supports simultaneous installation of multiple button types. Ideal for creating multi-style decoration on a single product, boosting production capacity up to 240-300 pieces per minute.

Automatic Feeding and Precise Positioning

The automatic button press machine features an advanced vibration plate feeder, eliminating the need for frequent tool changes when switching between different nail types.

Adjustable Speed and Pressure Control

The upper and lower differential speeds can be adjusted independently for different materials. When the material thickness changes, the automatic pressure unit adjusts strength accordingly to maintain optimal fastening.

Wide Button Compatibility

Suitable for round four-claw nails with diameters ranging from 2.0mm to 10.0mm, and square four-claw nails from 4.0mm to 10.0mm, making it highly versatile for various production needs.

3D Adjustable Nail Feed Nozzle

The nozzle can be adjusted across three axes, allowing flexible positioning even for complex shapes like square, round, cone, or water breaker-style nails.

Durability and Longevity

Featuring high-strength components and a wear-resistant vibration plate, this metal button press machine delivers long service life and stable performance even in high-volume production environments.

Product Specifications

| Model No. | JYL-A6-6 |

|---|

| Working Area | 400 × 500 mm |

| Operating Speed | 240-300 PCS/min |

| Voltage | 110V-220V |

| Air Pressure Requirement | 5-6 KG/cm² |

| Nail Size Range | Square: 10-10.0 mm; Round: 4.0-9.0 mm |

| Machine Dimensions (L×W×H) | 2420 × 1550 × 1480 mm |

Application Areas

This Computerized Automatic Button Pressing Machine is widely used in:

Garment Manufacturing (Jeans, Jackets, Workwear, Outdoor Apparel)

Footwear Production (Shoes, Boots)

Bag and Luggage Assembly (Suitcases, Handbags, Backpacks)

Upholstery and Furniture Production (Sofa, Cushions)

Leather Goods Manufacturing (Belts, Accessories)

Other Button Pressing Solutions Available

For small-batch or craft production, our manual hand press button machines offer portability, ease of use, and cost-effectiveness. Ideal for prototyping, embossing, rivet setting, and small-scale fabrication.

Automatic Button Press Machine

Our range of automatic button press machines is designed for high-volume, repetitive tasks with programmable control, reducing labor intensity and ensuring consistent pressing force and placement accuracy.

Metal Button Press Machine

The metal button press machine is specifically engineered for attaching metal snaps, rivet buttons, and industrial fasteners onto fabrics, leather, or synthetic materials. It provides firm and durable fastening, commonly used in fashion, textile, and accessory production.

Why Choose Our Industrial Button Pressing Machines?

With expertise in button fastening technology, we provide a wide range of industrial and manual button pressing machines, suitable for both mass production lines and customized manufacturing environments.

If you need custom machine configurations, OEM/ODM services, or require technical support, feel free to contact our sales team for professional consultation.